Servo sprayer for optimum performance of the new technology

Die casting industry in the most advantage of brand innovation products

Swinging arm structure design, high efficiency, and stability, to achieve maximum productivity

The highest production safety, the best atomization effect, a new show of the new technology level

Innovative advantages of the brand, the best value for money, is the most ideal casting enterprise customer choice

Product Features

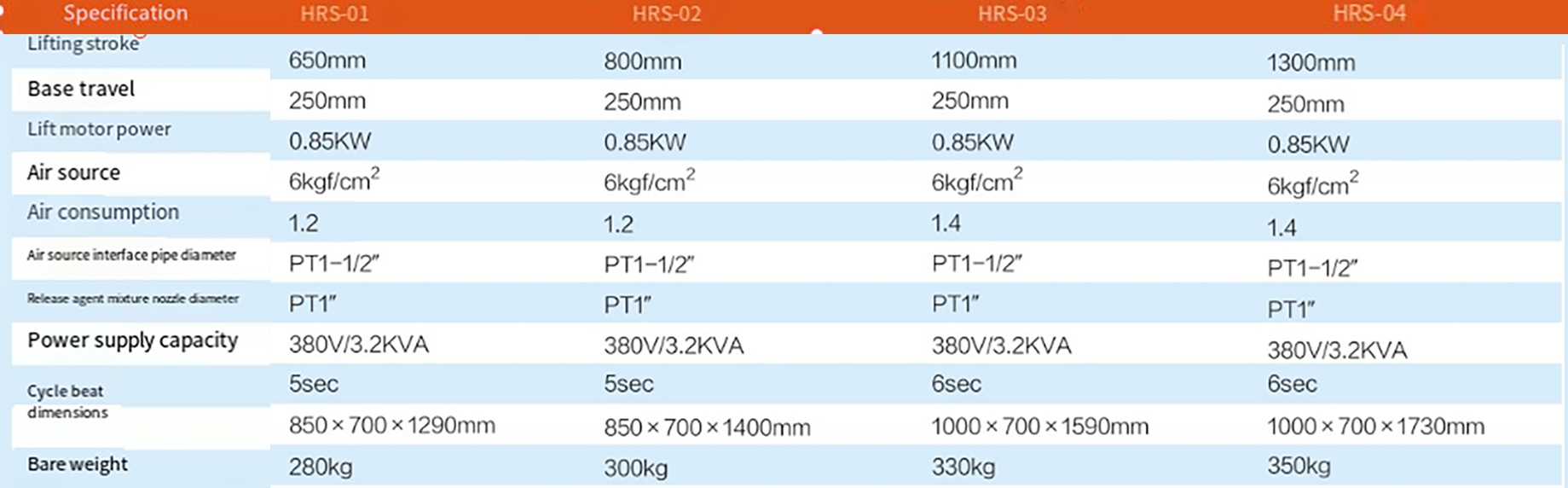

Rocker arm type structure, helical and worm gear reducer drive, high mechanical strength good stability.

Servo motor drive, with mold thickness adjusting function.

The man-machine interface touchscreen can be a variety of parameter settings, with fault diagnosis and display function, and convenient maintenance.

Store multiple sets of mold process, directly call stored mold replacement, convenient operation and maintenance

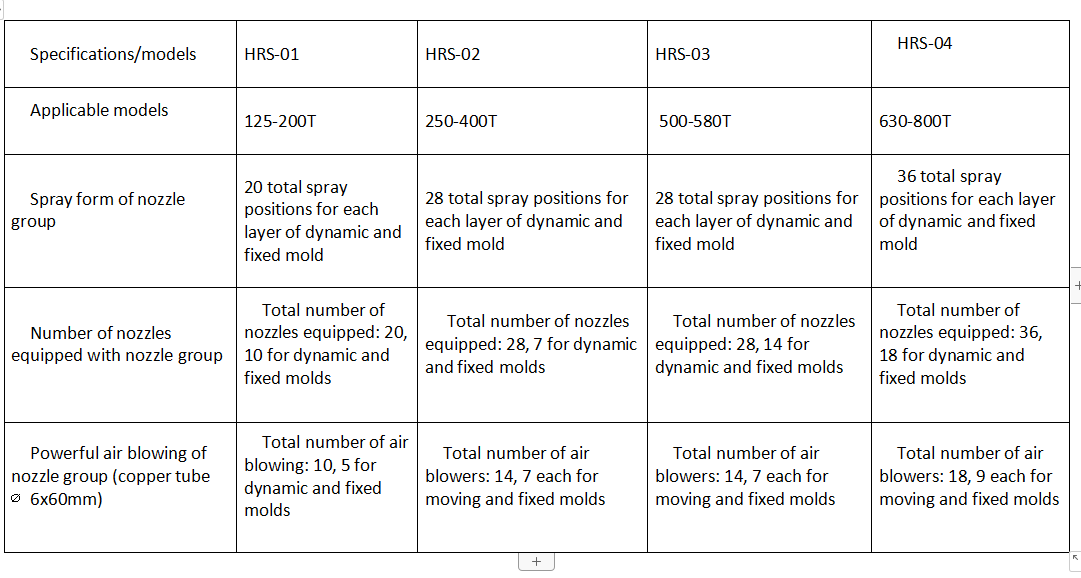

Bladder control nozzle (gas water), precise flow control, to meet the needs of different coating products.

Spraying and blowing can be individually controlled, intermittent, or continuous spray. independent strong blowing.

Equipped with a nozzle head group, with spray, spray, spray cycle floating function.

At the same time separately controlled blow, also spraying without blowing spray or not, has increased the air blowing system.

After the mold opening from the recent local spray standby, shorten the spray fall time, and improve the spray cycle.

And die casting machine into a semi-automatic operation, but also with the die casting machine, machine into a whole automated equipment

LEARN MORE ABOUT THE PRODUCT

Share your phone number, call you!