Hot Chamber Die Casting Gooseneck Introduction

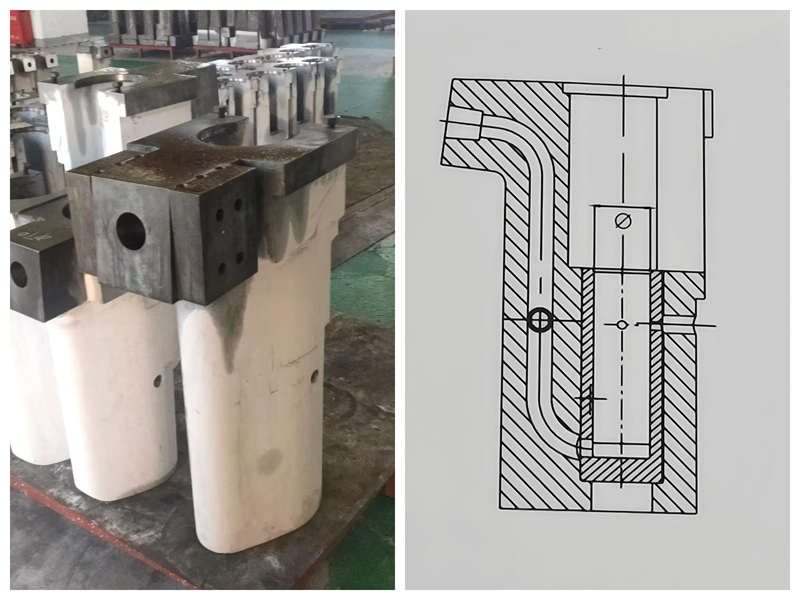

Gooseneck is an important part of the hot die casting machine, mainly used for melting and conveying molten metal.

It consists of two parts, the hopper and the bush pot. The hopper is mainly used to store and heat molten metal to ensure that the metal always remains flowing. The bush pot is the conduit before the molten metal enters the mold, which is mainly used to withstand the metal flow pressure during the injection process.

Advantages of Our Hot Chamber Die Casting Gooseneck:

Our hopper is made of high-temperature and corrosion-resistant cast iron, which can withstand the erosion of high-temperature alloys. It can quickly and evenly heat the molten metal, improve melting efficiency, and reduce energy consumption and the possibility of casting defects.

Our bush pot is manufactured through the vacuum high-pressure molding process to ensure high strength and precise size, and improve die-casting efficiency. Its high heat resistance can reduce the contamination of molten metal, maintain the purity of molten metal, and improve the quality of die castings.

Bush Pot Inside Diameter (unit: mm) :

MODEL | DC88 | DC100 | DC130 | DC200 |

Standard(⌀) | 50 | 55 | 60 | 70 |

Standby(⌀) | 45/55 | 60 | 65 | 60/65 |

This hot chamber die-casting gooseneck can be customized to meet your specific requirements, and we also have many other hot chamber die-casting hot work parts for you to choose from. If you have any special requests or need more information, please feel free to contact us. Our experts are ready to assist you with any questions.

LEARN MORE ABOUT THE PRODUCT

Share your phone number, call you!