A Comprehensive Analysis of Die Cast Tooling and Aluminum Materials

LK Die Casting Machine / 2024-07-24 16:21:47

2024-07-24 By Cherry

Introduction

In modern manufacturing, die casting technology is an important process for producing high-quality metal parts, especially in the automotive,

aviation and consumer electronics fields.

This article will explore the relevant knowledge of die cast tooling and aluminum materials in depth, including the design and

application of die cast tooling, the selection and characteristics of aluminum materials, and related technologies such as trivalent

chromate treatment and rapid prototype casting.

Basics of die casting molds

Design and function of die casting molds

Die cast tooling are crucial tools in the die cast process. Their design must take into account the working environment under

high temperature and high pressure.

The material of the mold is usually selected from high-strength alloys to ensure its service life and stability under high stress conditions.

Mold materials for die casting

Mold materials for die casting usually include high-strength steel and heat-resistant alloys.

These materials need to have good wear resistance, thermal conductivity, and thermal fatigue resistance to withstand repeated thermal cycles

in the die casting process.

Trivalent chromate treatment

Trivalent chromate treatment is an environmentally friendly surface treatment technology used to improve corrosion resistance and

hardness of molds.

Compared with traditional hexavalent chromium treatment, trivalent chromate is more environmentally friendly and complies with modern

environmental regulations.

Selection and application of aluminum materials

A360 aluminum alloy

A360 aluminum alloy is one of the commonly used materials in die cast tooling. It's excellent casting performance and mechanical

properties make it an ideal choice.

A360 aluminum has high strength, good corrosion resistance, and low density, making it suitable for a variety of high-performance applications.

Density of aluminum kg/mm³

The density of aluminum is 2.7 kg/mm³, which makes aluminum unique in terms of weight and strength.

The combination of low density and high strength makes aluminum widely used in industries such as aviation, automobiles, and electronics.

Magnesium sheet metal

Magnesium sheet metal is lightweight, has high strength, and good casting properties, making it an ideal material for manufacturing lightweight

components.

Magnesium sheet metal has a wide range of applications, from aerospace to consumer electronics.

Rapid Prototype Casting and Rapid Prototyping of Aluminium

Rapid Prototype Casting

Rapid prototyping casting is an innovative technology that allows designers to quickly create and test mold prototypes.

Through technologies such as 3D printing, rapid prototyping casting can significantly shorten the development cycle of new products

and improve the efficiency of design verification.

Rapid Prototyping Aluminium

Rapid prototyping aluminium technology makes the manufacture of complex aluminum parts more efficient.

This technology allows the rapid production of high-precision aluminum parts to meet the needs of different industries.

Application of aluminum prototypes

Aluminum prototypes play an important role in the development of new products.

They can be used for functional testing, design verification and marketing, helping companies to respond quickly to market needs.

Special parts of die cast tooling

Ideal 55 slider parts

The ideal 55 slider parts are one of the key parts in the die cast tooling, responsible for guiding and positioning the

moving part of the mold.

High precision and durability are important characteristics of the slider component, which directly affect the overall performance

of the mold.

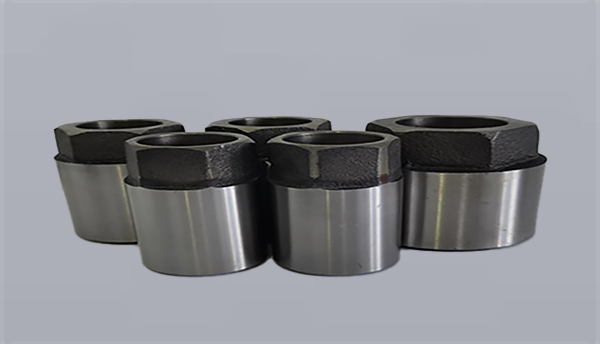

plunger tip for die casting machine

The plunger tip for die casting machine is a key component in the die casting process, and is responsible for injecting molten metal into the mold cavity.

The plunger tip for die casting machine needs to have high strength and wear resistance to ensure its stable operation under high temperatures and pressure.

Gating material

Gating material refers to the material used for the gate part of the mold, which usually needs to have high wear resistance and good

thermal conductivity. The choice of gate material directly affects the quality and production efficiency of die castings.

Application of aluminum in different fields

Aluminum caster

Aluminum casters are widely used in various mobile devices.

Their excellent wear resistance and lightweight properties make them an ideal choice.

The production of aluminum casters also relies on the high-precision manufacturing of tooling for die casting.

Wall aluminum

Wall aluminum is a commonly used decorative material in the construction industry, and its production also relies on high-precision

tooling for die casting. Wall aluminum is beautiful, durable, and easy to install.

Metal door components

Metal door components are mostly made by die-casting technology to ensure their durability.

These components usually need to have high strength and good surface quality to meet safety and aesthetic requirements.

Subcontracting of screw machining for the luxury sector

The luxury industry has extremely high requirements for the quality of screws, and usually uses precision processing and

subcontracting production to ensure the perfect quality of each screw.

Tooling for die casting plays an important role in this high-demand production process.

Subcontracting of screw-machining for household appliances

The home appliance industry has a large demand for screws and strict requirements and usually ensures production efficiency

and quality through processing subcontracting. High-precision die-casting molds are the key to ensuring the quality of screws.

Aluminium Gravity Die Casting

Aluminium gravity die casting is a traditional casting process that uses gravity to inject molten aluminum into a mold to produce

high-precision aluminum products.

This process is suitable for the production of large quantities of aluminum parts and has high production efficiency.

New Technologies and Future Developments

Transparent Chromate

Clear chromate is a material used for the surface treatment of aluminum products to improve their corrosion resistance

and surface gloss. The transparent chromate treatment significantly improves the appearance and performance of aluminum products.

ES Casting Metals

ES Casting Metals is a high-performance metal material widely used in the automotive and aviation fields.

Its production relies on high-precision die-casting molds to ensure its excellent mechanical properties and reliability.

Sigma Castings

Sigma Casting is a high-precision casting that is often used for high-demand mechanical parts. Its production relies on advanced

die-casting mold technology to ensure the quality and consistency of each casting.

We squeeze to please machine

This concept emphasizes the importance of equipment and process optimization in modern manufacturing. By continuously improving

die-casting machines and mold designs, production efficiency, and product quality can be significantly improved to meet changing market needs.

Nickel casting

Nickel castings have excellent corrosion resistance and high-temperature performance and are widely used in the chemical and power industries.

High-quality die-casting molds are the key to producing nickel castings, ensuring their reliability in harsh environments.

Conclusion

Through a comprehensive analysis of die-casting machine molds and aluminum materials, it can be seen that die-casting technology has

an irreplaceable and important position in modern manufacturing.

Whether it is material selection, process optimization, or the application of new technologies, every link affects the quality and

performance of the final product.

With the continuous advancement of technology, the application of die-casting molds and aluminum materials will be more extensive,

providing high-quality metal parts for all walks of life and promoting the development of the manufacturing industry.

Through this article, readers can better understand the relevant knowledge of die-casting molds and aluminum materials, and make

more wise choices in practical applications.

I hope this article can provide valuable information for readers and help them develop in their respective fields.

For more info, you can refer to: https://www.youtube.com/shorts/JLX410QV_kw

Contact LK Egypt to learn more info about the die-casting machine

LKAGENT OFFICE DCM

Address: Industry Zone, South of Port Said Kebly, Egypt

https://www.zazdiecasting.com/

Phone/WhatsApp/Wechat: +86 13598704163

Mobile: +20 101 304 3317 +20 150 181 8310

Email: jack@zazmae.com ahmedmahmoud@zazmae.com

OTHER CONTENT

-

2024-09-19 14:16:15 LK Cold Chamber Die Casting Machine DCC900 Locking Force: 9000KN Die Height: 400-1000mm Space Between Tie Bars: 930x930mm Shot Weight: 13.5Kg Casting Area Max:2250c㎡

More -

2024-09-19 14:11:06 LK Cold Chamber Die Casting Machine DCC280 Locking Force: 2800KN Die Height: 250-650mm Space Between Tie Bars: 560x560mm Shot Weight: 2.9Kg Casting Area Max:700c㎡

More -

2024-09-19 10:23:07 LK Cold Chamber Die Casting Machine DCC580 Locking Force: 5000KN Die Heigh: 350-850mm Space Between Tie Bars: 760x760mm Shot Weight: 6.9Kg Casting Area Max:1250c㎡

More -

2024-09-19 10:11:20 LK Cold Chamber Die Casting Machine DCC400 Locking Force: 4000KN Die Height: 300-700mm Space Between Tie Bars: 669x669mm Shot Weight: 4.7Kg Casting Area Max:1000c㎡

More