High-performance Aluminum-silicon Alloy: Promoting Lightweighting In The Automotive Industry

LK Die Casting Machine / 2024-08-19 16:43:14

High-performance aluminum-silicon alloy -- a revolutionary breakthrough in die-casting technology, helping the automotive industry move towards lightweight.

Aluminum-silicon alloy (Al-Si alloy) is widely used in automobile manufacturing, especially in die-casting technology. Due to its excellent casting properties, good mechanical strength, low density, excellent corrosion resistance, and thermal management capabilities, aluminum-silicon alloy has become an important material for modern automobiles' lightweight and high-performance requirements. This article will explore the key role of Al-Si alloy die castings in meeting these requirements.

This article will deeply explore the characteristics, production process, and application scenarios of ASM Al-Si Alloys Casts by die casting, and how to use die-casting machines to achieve the production of high-quality products, aiming to help users fully understand this material and quickly solve related problems.

1. What is Aluminum-Silicon Alloy?

Aluminum-Silicon alloy is a kind of aluminum alloy, mainly composed of aluminum and silicon elements, and the silicon content is usually between 5% and 30%. It has excellent casting properties and good mechanical properties, so it is widely used in structural parts that require lightweight and good corrosion resistance.

Main Features And Advantages:

Lightweight: The density of aluminum-silicon alloy is about 2.7 g/cm³, which is about one-third of steel, so it can effectively reduce the weight of the whole vehicle when used in automobile manufacturing.

Good castability: Al-Si alloy has good fluidity and less tendency to thermal cracking during solidification, so it is suitable for castings with complex shapes.

High strength and wear resistance: The silicon content of Al-Si alloy makes it have high wear resistance and is suitable for automotive parts with high workloads.

Excellent corrosion resistance: Silicon alloy has good corrosion resistance to the atmosphere, seawater, and chemical media, and is particularly suitable for automotive engines and heat exchangers.

Good thermal conductivity: Aluminum-silicon alloy has high thermal conductivity, which helps to improve the heat dissipation performance of heat source components such as engines, and improve the efficiency and reliability of engines.

2. The Role of Aluminum-Silicon Alloy In The Development of Lightweight Automobiles

Due to its excellent properties, aluminum-silicon alloy is widely used in many important parts of automobiles, especially in the die-casting process. The die-casting process can accurately control the shape and size of parts, reduce subsequent processing, improve production efficiency, and reduce manufacturing costs.

Engine Related Parts:

The engine is one of the most critical parts of the car, and aluminum-silicon alloy is widely used in engine-related parts.

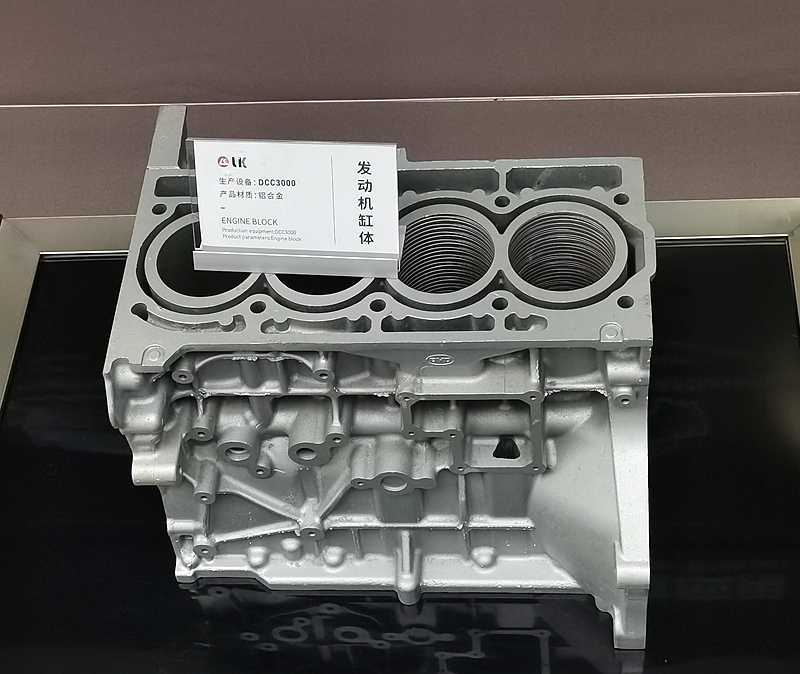

Engine block and cylinder head:

The engine block and cylinder head made of aluminum-silicon alloy by die casting are lightweight and have high strength and good heat dissipation. Aluminum silicon alloy can effectively reduce the weight of the engine and improve fuel efficiency. At the same time, it has sufficient rigidity and wear resistance to ensure the long-term operation of the engine.

(The engine block casting is cast by our die-casting machine.)

Turbocharger housing:

Turbochargers need to withstand high temperatures and high-pressure environments. The high-temperature resistance and good thermal conductivity of aluminum-silicon alloy make it an ideal material for manufacturing turbocharger housings.

Transmission And Drive System:

The transmission and drive systems are the core components of the automotive power system, requiring high strength and wear resistance.

Transmission housing:

The high strength and wear resistance of aluminum-silicon alloy makes it an ideal material for transmission housing. The die-cast transmission housing is not only light in weight but also can maintain a low-temperature rise at high speed, improving the working efficiency and life of the system.

Driveshaft:

The drive shaft needs to withstand large torque and pressure. Aluminum silicon alloy can reduce weight while ensuring strength, helping to improve the power transmission efficiency of the transmission system.

Suspension System And Body Structure:

The suspension system and body structure of the car are key components that affect safety and comfort. The application of aluminum-silicon alloy in these components helps to improve the performance of the car.

Suspension brackets and connectors:

Aluminum silicon alloy die-castings have been widely used in automobile suspension systems, including suspension brackets, control arms, and other connectors. The lightweight of these parts can improve the handling and comfort of the car while providing strong impact resistance to ensure the safety of the car during driving.

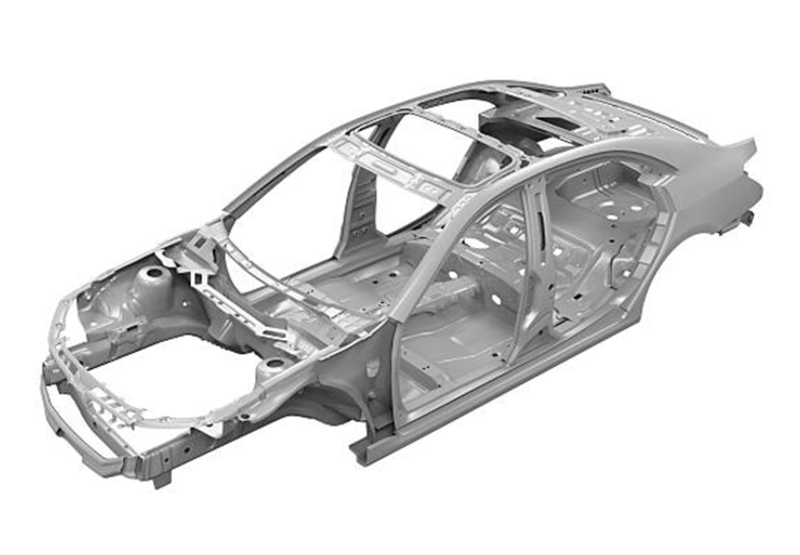

Body frame:

The body frame made of aluminum-silicon alloy die-casting has excellent strength and rigidity, and can effectively reduce the weight of the body, improving the fuel economy and dynamic performance of the whole vehicle.

Wheels And Brake System:

The wheels and brake system are key components that affect the handling and safety of the car. The lightweight properties of aluminum-silicon alloys make these parts widely used in die-casting.

Aluminum alloy wheels:

Aluminum silicon alloys are widely used in the production of aluminum alloy wheels due to their low density and high strength. Compared with traditional steel wheels, aluminum alloy wheels can effectively reduce vehicle weight, improve vehicle fuel efficiency, and have better corrosion resistance.

Brake calipers and brake discs:

The application of aluminum-silicon alloys in brake systems, especially brake calipers and brake discs, can reduce the overall weight of the system, improve thermal management, prevent brake overheating, and improve braking performance.

Electronic System Housing:

Modern cars are increasingly dependent on electronic systems, and the excellent thermal conductivity of aluminum-silicon alloys makes it an ideal material for electronic system housings.

Battery housing and electronic control system housing:

Aluminum silicon alloys are widely used in battery housings and electronic control system housings of electric vehicles. These components need to have good heat dissipation to maintain the stable operation of batteries and electronic systems. At the same time, the lightweight properties of aluminum-silicon alloys can help reduce the weight of the entire vehicle and improve the endurance of electric vehicles.

3. Future Development Trends

With the continuous advancement of technology, the development prospects of aluminum-silicon alloy die castings are very broad.

On the one hand, the development of materials science will continuously optimize the composition and properties of aluminum-silicon alloys, making them more adaptable to the needs of different fields. On the other hand, the continuous innovation of die-casting processes and die-casting machines will further improve the quality and production efficiency of die-castings.

At the same time, the requirements of environmental protection and sustainable development will also promote the manufacturing of aluminum-silicon alloy die-castings in a more green and energy-saving direction. For example, the use of new die-casting lubricants and the recycling of die-casting waste will help reduce the impact on the environment.

4. Conclusion:

Aluminum-silicon alloy die-castings, as an important manufacturing material, have become the preferred material for many industries due to its excellent performance and its wide range of applications and excellent performance. By reasonably selecting die-casting machines, optimizing production processes, and strengthening quality management, manufacturers can produce high-quality Al-Si alloy die-castings to meet the strict needs of the market.

With the continuous advancement of technology and the continuous changes in market demand, it is believed that aluminum-silicon alloy die-castings will continue to play an important role in the future and provide strong support for the development of various fields.

The die-casting industry will continue to promote the application of Al-Si alloys and help the further development of the manufacturing industry. Suppose you are looking for ways to improve product quality or need to gain a deeper understanding of the application of Al-Si Alloys Casts by Die Casting. In that case, this article will be your indispensable reference.

If you want to know more about our die-casting machines or die-casting technology, please visit our website or contact us.

Arabic Website: https://ae.zazdiecasting.com/

English Website: https://www.zazdiecasting.com/

Phone/WhatsApp/Wechat: 0086 13598704163

Mobile: +20 101 304 3317 +20 150 181 8310

Email: jack@zazmae.com ahmedmahmoud@zazmae.com

OTHER CONTENT

-

2024-09-19 14:16:15 LK Cold Chamber Die Casting Machine DCC900 Locking Force: 9000KN Die Height: 400-1000mm Space Between Tie Bars: 930x930mm Shot Weight: 13.5Kg Casting Area Max:2250c㎡

More -

2024-09-19 14:11:06 LK Cold Chamber Die Casting Machine DCC280 Locking Force: 2800KN Die Height: 250-650mm Space Between Tie Bars: 560x560mm Shot Weight: 2.9Kg Casting Area Max:700c㎡

More -

2024-09-19 10:23:07 LK Cold Chamber Die Casting Machine DCC580 Locking Force: 5000KN Die Heigh: 350-850mm Space Between Tie Bars: 760x760mm Shot Weight: 6.9Kg Casting Area Max:1250c㎡

More -

2024-09-19 10:11:20 LK Cold Chamber Die Casting Machine DCC400 Locking Force: 4000KN Die Height: 300-700mm Space Between Tie Bars: 669x669mm Shot Weight: 4.7Kg Casting Area Max:1000c㎡

More