C45e

LK Die Casting Machine / 2024-09-12 10:07:15

C45e, as a common carbon steel material, is widely used in various industrial manufacturing. Although C45E steel is usually used in machinery manufacturing and engineering

parts, and its potential application in the die-casting industry

is also worth exploring.

This article will explore the characteristics of C45E

steel and its application in die-casting machines in

depth to help readers understand the relationship between

the two and provide a reference for those interested in

the die-casting process.

What is C45E?

C45E steel is a medium carbon steel with specific properties.

It has good strength, toughness, and hardness characteristics

and good machinability. This type of steel has a carbon

content between 0.42% and 0.50% and is suitable for tempering

to improve its hardness and wear resistance.

C45E steel has a wide range of applications in the following

fields:

1. Manufacturing of mechanical parts: such as shafts, gears,

bolts, etc.

2. Automotive industry: used for parts that need to withstand

high strength and fatigue loads.

Features of C45E include:

1. High strength and hardness

2. Good machinability

3. Performance can be further enhanced by quenching and

tempering

4. Suitable for manufacturing mechanical parts with heavy

loads

The high strength of C45E enables parts produced by die-casting

machines to withstand heavy loads and stresses. Whether it

is to withstand complex mechanical forces in the automobile

manufacturing or face various harsh working environments

in the field of mechanical engineering, parts produced by

C45E die-casting machines can function reliably.

During the operation of the die-casting machine, the good

toughness of C45E steel ensures that the parts are not prone

to cracks and other defects during the high-speed filling of

the molten metal. This is crucial to ensure the quality of

the die-casting products. Because even a small crack can

cause the part to fail during use, with serious consequences.

Although C45E steel differs from die-casting metals (such as

aluminum, zinc, etc.), its mechanical properties make it ideal

for some die-casting machine parts.

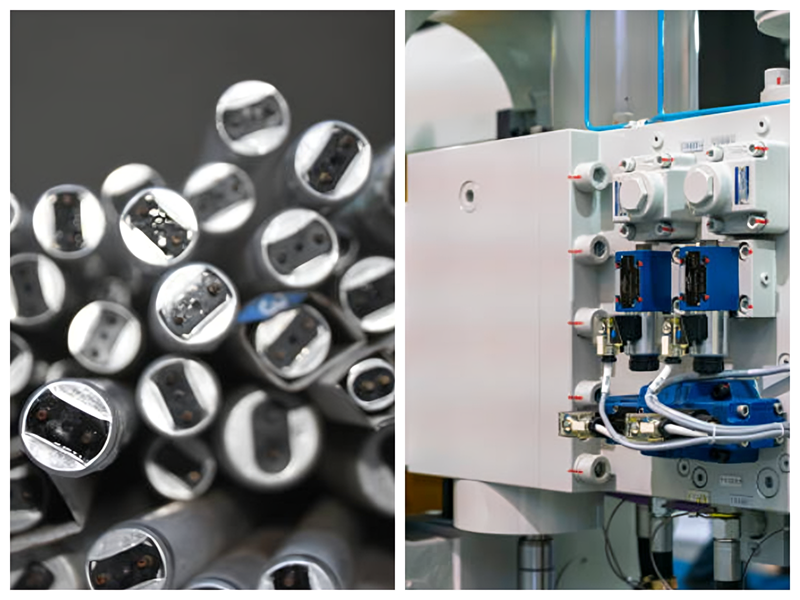

The role of the die-casting machine

The die-casting machine is an indispensable piece of equipment

in the modern manufacturing industry. It is mainly used to

inject molten metal into the mold under high pressure to

produce parts with complex shapes. Die-casting machines are

divided into two main types according to their working

principles:

Hot chamber die casting machine: suitable for metals with

lower melting points, such as zinc, magnesium, etc.

Cold chamber die casting machine: used for metals with higher

melting points, such as aluminum and copper.

During the die-casting process, the material of the mold

and the structural design of the die-casting machine have

an important influence on the quality and life of the casting.

The manufacturing material of the die-casting machine must

have high strength, heat resistance, and fatigue resistance,

and C45E has these advantages.

The relationship between C45E and die-casting machine

Although C45E itself is not the main metal material used in

the die-casting process (such as zinc, aluminum, etc.), it

has its unique advantages as a core component material of

the die-casting machine. The following are the specific

applications of C45E steel in die-casting machines:

1. Die casting machine mold bracket

The molded bracket of the die-casting machine needs to

withstand high temperatures, high pressure, and frequent

mechanical stress. The high strength and good fatigue resistance

of C45E steel make it an ideal material for manufacturing mold

brackets. Through quenching and tempering treatment, C45E can

further improve its hardness and wear resistance and extend

the service life of the molded bracket.

2. Die-casting machine drive shaft

The drive shaft in the die-casting machine must have sufficient

strength to withstand long-term high-intensity work. After

quenching and tempering, the surface hardness of C45E steel

increases, and it has excellent toughness, which can cope

with the frequent start-up and shutdown operations in the

die-casting machine.

3. Other key parts of the die-casting machine

In addition, the machinability of C45E steel also facilitates

the manufacture of die-casting machine-related parts. Whether

it is the precise machining of molds or manufacturing and

maintenance of other key parts on the die-casting machine,

C45E can meet the requirements of the processing technology.

In addition to mold brackets and drive shafts, C45E can also

be used for various sliding parts and bearings in die-casting

machines. These parts face high-frequency friction and wear

during operation, and the high hardness and good machinability

of C45E steel makes it an ideal choice for these parts.

Possible Applications of C45E in Die-casting Molds

From the perspective of molds, C45E can be used to make

die-casting molds. High-quality die-casting molds are the

basis for efficient production of die-casting machines.

The molds made of C45E steel can withstand the repeated

high temperature, high-pressure impact, and erosion of

molten metal during the die-casting process. Its wear

resistance ensures the service life of the mold and reduces

the cost and time consumption caused by frequent mold

replacement.

In addition, the machinability of C45E steel also facilitates

the manufacture of die-casting machine-related parts.

Whether it is precise machining of the mold or manufacturing

and maintenance of other key components on the die-casting

machine, C45E can meet the requirements of the processing

technology.

In actual production, engineers need to adjust carefully

the parameters of the die-casting machine to ensure that

C45E steel can be die-cast under the best conditions.

For example, the parameters such as die-casting pressure,

temperature and filling speed are reasonably set so that

the C45E molten metal can evenly fill the mold cavity

to avoid defects such as shrinkage and pores.

Although C45E is mainly used in the manufacture of die-casting

machines rather than as a die-casting material itself, its

application in the manufacture of some die-casting molds

is also worth studying. Die-casting molds require materials

to have high heat resistance and deformation resistance, and

C45E which has been quenched and tempered has a certain

ability to resist high temperatures.

Therefore, C45E can be used as an auxiliary material for

some die-casting molds, especially in the mold-bearing part

or mold frame.

Combination of C45E and die-casting process: Prospects with the continuous advancement of industrial manufacturing, the complexity and precision requirements of die-casting processes are getting higher and higher. In this context,

the die-casting machine parts must have higher-performance materials. C45E steel, due to its advantages in strength, hardness, and processing performance, is expected to play a more important role in the manufacture of die-casting machines.

Future Outlook

In the future, with the continuous improvement of C45E material

technology, such as through surface coating technology or heat

treatment technology, further enhancing its wear resistance

and corrosion resistance, C45E may occupy a place in certain

areas of die-casting molds and become an important material

in the manufacture of key parts of die-casting machines.

With the continuous advancement of science and technology,

the combination of C45E and die-casting machines is also

constantly innovating and developing. New die-casting technologies

continue to emerge, further tapping the potential of C45E

steel for use in die-casting machines. For example, vacuum

die-casting technology can effectively reduce the pores in

the castings and improve the density and mechanical properties

of C45E die-casting parts.

In terms of environmental protection, the cooperation between

C45E and die-casting machines also have positive significance.

Efficient die-casting production can reduce material waste,

and the recyclability of C45E steel is also in line with

the concept of sustainable development of modern industry.

In general, there is a complementary relationship between

C45E and die-casting machines. With its excellent performance,

C45E provides a high-quality material basis for the production

of die-casting machines, while die-casting machines provide

efficient and precise processing means for the forming of

C45E steel.

This close combination has created huge value in the industrial

manufacturing and promoting the development and progress

of various industries. Whether in the aerospace field

that pursues high performance or on a large scale

production of automobiles, home appliances, and other

industries, the perfect collaboration between C45E and

die-casting machines have laid a solid foundation for

the manufacture of high-quality products.

However, we cannot ignore the challenges that may be faced

in the process of combining C45E with die-casting machines.

For example, the cost of C45E steel is relatively high, which

requires optimized design and process in the production process

to ensure maximum cost-effectiveness. At the same time, the

operation and maintenance of die-casting machines require

professional technicians, and the training and skill improvement

of operators is also an important link.

In the future development, we can expect that the relationship

between C45E and die-casting machines will be closer. With

the further development of materials science, there may be

steels similar to C45E with better performance, which will

open up new space for the application of die-casting machines.

At the same time, the intelligent development of die-casting

machines will also bring more convenience and higher efficiency

to the die-casting production of C45E steel. We must continue

to explore and innovate, give full play to the advantages

of C45E and die-casting machines, and make greater contributions

to the prosperity of industrial manufacturing.

Conclusion

Although C45E steel is not the main casting metal used in

die-casting machines, it plays a vital role in die-casting

machine manufacturing. As a high-strength, medium-carbon steel,

C45E provides a reliable material choice for the core components

of die-casting machines with good quenching and tempering

properties, excellent hardness, and wear resistance.

With the advancement of industrial manufacturing technology,

C45E has broad application prospects in die-casting machine

manufacturing.

Through this article, we hope to help readers better understand

the relationship between C45E and die-casting machines, and provide

valuable reference information for those who are interested

in the die-casting process and material selection.

For more info, you can refer to:

https://www.tiktok.com/@lk_diecastingmachine/video/7405113006880820522

https://www.youtube.com/shorts/JLX410QV_kw

To learn further info about Die Casting Machines,

pls contact LK Die Casting Machine Authorized Official Agent

LK OFFICIAL AGENT OFFICE DCM

LK Die Casting Machine Authorized Official Agent for Egypt(EGY)

Saudi Arabia(KSA)

United Arab Emirates(UAE)

The Islamic Republic of Iran(Iran)

Qatar(QAT)

The State of Kuwait(Kuwait)

The Middle East

Address:

1. Industry Zone, South of Port Said Kebly, Cairo, Egypt

2. EX 14., EASTERN RING ROAD, AI RAYAN DISTRICT,

RIYADH, SAUDI ARABIA

Arabic Website: https://ae.zazdiecasting.com/

English Website: https://www.zazdiecasting.com/

Phone/WhatsApp/Wechat: 0086 13598704163

Mobile: +20 101 304 3317 +20 150 181 8310

Email: jack@zazmae.com ahmedmahmoud@zazmae.com

OTHER CONTENT

-

2024-09-19 14:16:15 LK Cold Chamber Die Casting Machine DCC900 Locking Force: 9000KN Die Height: 400-1000mm Space Between Tie Bars: 930x930mm Shot Weight: 13.5Kg Casting Area Max:2250c㎡

More -

2024-09-19 14:11:06 LK Cold Chamber Die Casting Machine DCC280 Locking Force: 2800KN Die Height: 250-650mm Space Between Tie Bars: 560x560mm Shot Weight: 2.9Kg Casting Area Max:700c㎡

More -

2024-09-19 10:23:07 LK Cold Chamber Die Casting Machine DCC580 Locking Force: 5000KN Die Heigh: 350-850mm Space Between Tie Bars: 760x760mm Shot Weight: 6.9Kg Casting Area Max:1250c㎡

More -

2024-09-19 10:11:20 LK Cold Chamber Die Casting Machine DCC400 Locking Force: 4000KN Die Height: 300-700mm Space Between Tie Bars: 669x669mm Shot Weight: 4.7Kg Casting Area Max:1000c㎡

More