Screw Machining of Parts in Special Alloys

LK Die Casting Machine / 2024-10-12 14:15:07

In modern manufacturing, die-casting machines have become indispensable, especially in producing metal parts with complex shapes. The application of screw processing of special alloy parts in die-casting machines not only improves the quality and performance of products but also improves production efficiency and cost-effectiveness.

This article will explore this topic and combine practical cases to help readers better understand the advantages and applications of this technology.

Die Casting Technology

The working principle of a die-casting machine is similar to

injection molding, but the material it processes is metal.

First, the liquid metal is poured into the furnace and

heated to a suitable temperature to keep it in good fluidity.

Then, the injection system quickly injects the liquid metal into the mold cavity under high

pressure. In the mold, the liquid metal cools and solidifies

rapidly to form the desired part shape. Finally, the die-casting

The machine's mold opening system opens the mold and removes

the molded part.

Screw processing of special alloy parts

1. Selection of special alloy materials

In the die-casting machine, the screws of special alloy parts

usually need to withstand harsh working conditions such as high

temperature, high pressure, and high wear, so the performance

requirements of the material are very high. In the process

of screw processing, it is very important to select the right

special alloy. Common special alloys include high-temperature

alloys, titanium alloys, aluminum alloys, magnesium alloys,

copper alloys, stainless steel, etc.

These alloys have excellent mechanical properties, high-temperature

strength, corrosion resistance, wear resistance, and machinability,

and are suitable for high-demand application scenarios.

When we choose alloys, we usually need to consider the following

factors:

1. Strength and toughness: Special alloys should have high tensile strength and toughness to withstand various stresses in use.

2. Corrosion resistance: Screws used in specific environments must have good corrosion resistance to extend their service life.

3. Machinability: The machinability of the alloy affects the processing efficiency and cost.

Screw processing technology

The processing technology of screws usually includes cutting,

forming and heat treatment. For example, cutting is high-precision

cutting through CNC machine tools, which can ensure the accuracy

and surface finish of the thread; cold heading is the use of

high pressure to shape the metal, which is suitable for mass

production, saving materials and processing time; heat treatment

is the heat treatment of special alloy screws, which can improve

their hardness and wear resistance.

1. Turning

Turning is one of the most commonly used methods in screw processing.

The turning tool cuts on the rotating workpiece to remove excess

material and form the shape of the screw. During the turning process,

attention should be paid to the selection of tools, the setting

of cutting parameters, and the clamping of the workpiece to ensure

processing accuracy and surface quality.

2. Milling

Milling can also be used for screw processing. The thread of the

screw is milled on the workpiece by a milling cutter. The advantage

of milling is high processing efficiency and is suitable for mass

production. However, the accuracy of milling is relatively low, and

subsequent grinding or polishing processes are required to improve it.

3. Grinding

Grinding is a high-precision processing method, which is often

used in occasions where high dimensional accuracy and surface

roughness of screws is required. By grinding on the workpiece

with a grinding wheel, a small amount of material is removed to

enable the screw to achieve the required accuracy and surface

quality.

4. Thread processing

Thread processing is a key link in screw processing. Common

thread processing methods include turning thread, milling

thread, tapping, and threading. When choosing a thread processing

method, it is necessary to comprehensively consider factors

such as the size, accuracy requirements, and production batch

of the screw.

Quality control of screw processing

1. Dimensional accuracy control

The dimensional accuracy of the screw directly affects its

assembly performance and use effect. During the processing,

the size of the screw needs to be measured by measuring tools,

and the processing parameters need to be adjusted in time to

ensure that the dimensional accuracy meets the requirements.

2. Surface quality control

The surface quality of the screw has an important influence

on its corrosion resistance and wear resistance. During the

processing, it is necessary to select appropriate tools and

cutting parameters to avoid surface scratches, burrs, and

other defects. At the same time, the surface of the screw

can be treated by polishing, grinding, and other processes

to improve the surface quality.

3. Mechanical property control

The screws of special alloy parts need to have good mechanical

properties, such as strength, hardness, toughness, etc. During

the processing, the screws need to be treated by a reasonable

heat treatment process to improve their mechanical properties.

At the same time, the mechanical properties of the screws need

to be tested to ensure that they meet the design requirements.

Combination of die-casting machine and screw

processing

The application of die-casting machine in screw processing can

not only achieve high-efficiency production but also ensure

the consistency and accuracy of parts. For example, in automobile

manufacturing, aluminum alloy screws produced by die-casting

machines are not only light in weight but also high in strength,

meeting the dual requirements of modern automobiles for weight

reduction and safety.

Application of screws of special alloy parts in die-casting machines

1. Application of screws in the clamping mechanism

In the clamping mechanism of the die-casting machine, screws

play the role of connecting and tightening the mold. Since the

clamping mechanism needs to withstand huge clamping forces during

the die-casting process, the strength and rigidity requirements

of the screws are very high. The screws of special alloy parts can

meet this requirement, ensuring that the mold will not loosen or

deform during the die-casting process, thereby ensuring the

dimensional accuracy and quality of the product.

2. Application of screws in the injection mechanism

The injection mechanism is one of the core components of the

die-casting machine and its function is to inject liquid metal

into the mold cavity. In the injection mechanism, screws are

used to connect and fix the injection cylinder, injection rod

and other components. Since the injection mechanism needs to

withstand high temperature, high pressure, and high wear during

the operation, higher requirements are placed on the material

and processing technology of the screws. The screws of special

alloy parts can maintain good performance under harsh working

conditions and ensure the stable operation of the injection

mechanism.

3. Application of screws in hydraulic system

The hydraulic system is the power source of the die-casting

machine and its function is to provide power for each action

of the die-casting machine. In the hydraulic system, screws

are used to connect and fix hydraulic components such as oil

pumps, oil cylinders, valves, etc. Due to the high working

pressure in the hydraulic system, the sealing performance and

strength requirements of the screws are very high. The screws

of special alloy parts can meet this requirement, ensure the

normal operation of the hydraulic system, and avoid leakage

and other faults.

Advantages of screw processing of special alloy parts in die casting machine applications

1. Improving the performance and stability of the die-casting machine

The screws of special alloy parts have good high-temperature

strength, corrosion resistance, and wear resistance, and can

maintain good performance under harsh working conditions. The

use of screws of special alloy parts can improve the performance

and stability of the die-casting machine, reducing equipment

failures and downtime, and improve production efficiency.

2. Extending the service life of the die-casting machine

The screws of special alloy parts can withstand harsh working

conditions such as high temperature, high pressure, and high

wear, and are not prone to deformation, fracture, and other

damage. The use of screws of special alloy parts can extend

the service life of the die-casting machine and reduce equipment

maintenance costs.

3. Improve product quality

The screws of special alloy parts can ensure that the mold will

not loosen or deform during the die-casting process, thereby

ensuring the dimensional accuracy and quality of the product.

At the same time, the screws of special alloy parts can also

improve the stability of the injection mechanism and hydraulic

system, and reduce product defects and scrap rates.

Problems and solutions for screw processing of special alloy parts in die-casting machine applications

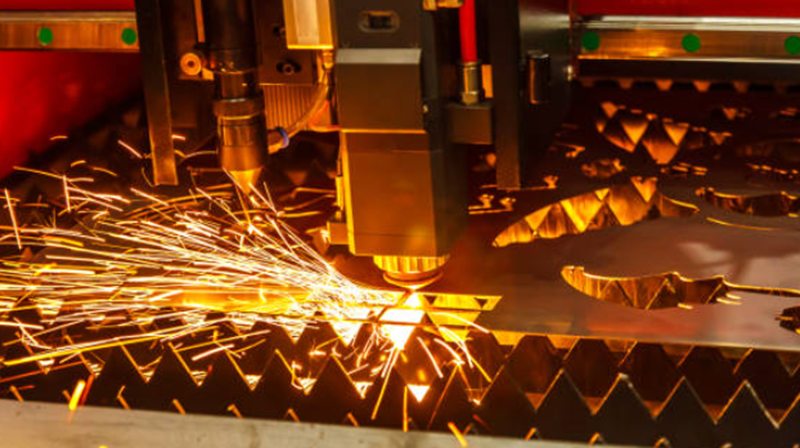

1. Difficulty in processing

Special alloy materials have high hardness and good toughness

and are difficult to process. During the processing, problems

such as tool wear and poor surface quality are prone to occur.

To solve these problems, appropriate tools and cutting

parameters can be selected, and advanced processing technology

such as high-speed cutting and laser processing can be adopted.

2. High cost

The price of special alloy materials is high and the processing

technology is complex, resulting in a high cost of screws for

special alloy parts. To reduce costs, costs can be

reduced by optimizing the design, improving material utilization,

and adopting mass production.

3. Difficulty in quality inspection

The screws of special alloy parts have high requirements for

dimensional accuracy, surface quality, and mechanical properties,

and quality inspection is difficult. To ensure quality, advanced

testing equipment and testing methods, such as three-coordinate

measuring instruments, hardness testers, tensile testing machines,

etc., can be used to conduct comprehensive testing and analysis

of screws.

User Experience and Future Outlook

With the development of science and technology, the combination

of die-casting machines and special alloy screw processing will

continue to deepen. In the future, intelligent manufacturing

and automation will become the trend in this field, making the

production process more efficient and flexible. At the same time,

user experience will be further improved, and customers can customize

higher-performance screws according to specific needs.

Conclusion

The screw processing of special alloy parts has a wide range of

applications in die-casting machines, which is changing the

traditional manufacturing methods and promoting the progress

of the industry. It is not only related to the performance and

stability of the die-casting machine, but also directly affects

the quality and production efficiency of the product.

By selecting, suitable special alloy materials, optimizing the

processing technology, combining advanced die-casting technology,

and strengthening quality control, processing quality, and

performance of screws of special alloy parts can be improved

to meet the use requirements of die-casting machines. At the

same time, we should continue to explore and innovate, develop

more advanced processing technologies and materials, and make

greater contributions to the development of the die-casting industry.

OTHER CONTENT

-

2024-09-19 14:16:15 LK Cold Chamber Die Casting Machine DCC900 Locking Force: 9000KN Die Height: 400-1000mm Space Between Tie Bars: 930x930mm Shot Weight: 13.5Kg Casting Area Max:2250c㎡

More -

2024-09-19 14:11:06 LK Cold Chamber Die Casting Machine DCC280 Locking Force: 2800KN Die Height: 250-650mm Space Between Tie Bars: 560x560mm Shot Weight: 2.9Kg Casting Area Max:700c㎡

More -

2024-09-19 10:23:07 LK Cold Chamber Die Casting Machine DCC580 Locking Force: 5000KN Die Heigh: 350-850mm Space Between Tie Bars: 760x760mm Shot Weight: 6.9Kg Casting Area Max:1250c㎡

More -

2024-09-19 10:11:20 LK Cold Chamber Die Casting Machine DCC400 Locking Force: 4000KN Die Height: 300-700mm Space Between Tie Bars: 669x669mm Shot Weight: 4.7Kg Casting Area Max:1000c㎡

More