Technique Report: Inspection and Maintenance of 280T Die Casting Machine

LK Die Casting Machine / 2025-04-18 17:25:21

Inspection and Maintenance of Our Client's 280T Die Casting Machine

Prepared for: [ Client Company ]

Date: 2025-4-15

Location: EGYPT

Machine Model: 280T Die Casting Machine

Inspected by: Jeff Zhang from ZAZ

( Real pictures from our engineers' maintenance site in Egypt. )

1. Executive Summary

During a manual mold-opening and closing inspection, severe tie-bar instability was detected, caused by loosened cover plate screws. This led to misalignment, accelerated wear of critical components (bushings, steel belts), and platen sinking. Corrective actions restored parallelism to 0.2mm, but worn parts require replacement. A preventive maintenance plan is proposed to mitigate future failures.

2. Findings & Corrective Actions

1) Identified Issues

-Tie Bar Misalignment: Loose cover plate screws caused tie bars to shift, creating 1mm parallelism deviation.

-Resulting friction damage: Bronze bushings and dust seals. Steel belts and slide shoes, leading to the movable platen sinking.

-Production Impact: Risk of mold flash due to misalignment.

2) Actions Taken

-Realigned tie bars, reducing parallelism deviation to 0.2mm.

-Secured all cover plate screws to prevent future movement.

-Tested mold closure: Confirmed no flash during trial production.

3) Critical Replacement Parts

The following components require immediate replacement to avoid further damage:

Worn Parts: Steel belts & slide shoes. Bronze bushings & dust seals.

Urgency: Delayed replacement may worsen tie bar scoring and platen instability.

4) Root Cause & Prevention Plan

- Root Cause

Insufficient maintenance routines led to: Undetected loose fasteners. Inadequate lubrication of tie bars/bushings. Unchecked wear on sliding components.

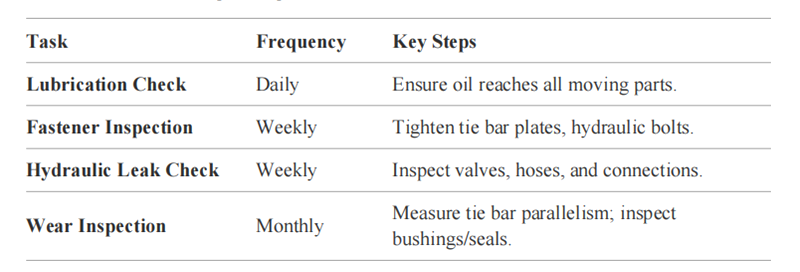

-Preventive Maintenance Plan

To extend machine lifespan, implement:

5) Recommendations for [ Client Company ]

- Schedule Downtime to replace worn parts (steel belts, bushings, seals).

- Staff Training on daily/weekly checks (we can assist upon request).

- Spare Parts Inventory: Keep critical components (e.g., bushings, seals) on hand.

Conclusion

The tie-bar issue was resolved temporarily, but proactive maintenance is essential to avoid platen misalignment and costly downtime. Implementing daily/weekly checks will extend component lifespan and ensure production stability.

With over a decade of deep involvement in Egypt’s die-casting industry, our team of professional engineers is committed to providing fast, reliable, and expert support tailored to local manufacturers. As the official agent of LK Group in Egypt, we offer on-site installation, troubleshooting, and regular maintenance services — all backed by locally stocked spare parts and repair capabilities.

Whether you're upgrading your production line or need immediate technical assistance, we are right here in Egypt, ready to support your success.

Contact us today to schedule a visit or request spare parts availability.

OTHER CONTENT

-

2024-09-19 14:16:15 LK Cold Chamber Die Casting Machine DCC900 Locking Force: 9000KN Die Height: 400-1000mm Space Between Tie Bars: 930x930mm Shot Weight: 13.5Kg Casting Area Max:2250c㎡

More -

2024-09-19 14:11:06 LK Cold Chamber Die Casting Machine DCC280 Locking Force: 2800KN Die Height: 250-650mm Space Between Tie Bars: 560x560mm Shot Weight: 2.9Kg Casting Area Max:700c㎡

More -

2024-09-19 10:23:07 LK Cold Chamber Die Casting Machine DCC580 Locking Force: 5000KN Die Heigh: 350-850mm Space Between Tie Bars: 760x760mm Shot Weight: 6.9Kg Casting Area Max:1250c㎡

More -

2024-09-19 10:11:20 LK Cold Chamber Die Casting Machine DCC400 Locking Force: 4000KN Die Height: 300-700mm Space Between Tie Bars: 669x669mm Shot Weight: 4.7Kg Casting Area Max:1000c㎡

More