Application of Die Casting Machines In The Automotive Industry

LK Die Casting Machine / 2024-10-23 16:03:06

2024-10-23 by Dawn

The automotive industry occupies an important position in the global economy. With the increasing trend of electrification, lightweight, and intelligence, the production process of automotive parts is constantly optimized.

In this context, die-casting machines have become indispensable in automobile manufacturing. Its advantages in high precision and mass production help the automotive industry achieve product quality and production efficiency. This article will discuss the main applications, technical advantages, and future development trends of die-casting machines in the automotive industry.

The Working Principle of Die Casting Machine

The core working principle of the die-casting machine is to hydraulically inject molten metal into the mold, and then form precision parts after cooling and solidification. Depending on the metal material, the die casting process is mainly divided into cold chamber die casting and hot chamber die casting.

By quickly filling the mold with high pressure, the die-casting machine can produce parts with complex shapes and high precision. This process is particularly critical in the automotive industry because automotive parts have strict requirements on precision, strength, and weight. Since parts usually need to use light metals such as aluminum and magnesium in automobile manufacturing, cold chamber die-casting machines have become the preferred equipment.

Advantages of Die-Casting Machines in Automotive Parts Production

Efficient Production

The biggest advantage of a die-casting machine is its ability to produce high-quality parts quickly. Compared with traditional machining, the die-casting process reduces material waste and significantly improves production efficiency. Since die-cast parts require almost no secondary processing after forming, this process is especially suitable for the automotive industry to produce parts in large quantities, such as engine blocks, gearbox housings, wheel brackets, etc.

Reduce Body Weight

Lightweighting is one of the key trends in modern automobile manufacturing. Light metal materials such as aluminum alloys and magnesium alloys are widely favored because of their lightweight and high strength. Die-casting machines can produce lightweight complex parts without compromising strength, helping automakers reduce body weight to improve fuel efficiency or extend the range of electric vehicles.

Accuracy And Consistency

Modern automotive parts have very high precision requirements, especially in safety and performance-related parts, and any slight error may lead to serious consequences. The die-casting machine can ensure the consistency of each batch of parts through precise molds and automated control systems, thereby ensuring stable quality in automobile manufacturing.

Typical Applications of Die Casting Machines in The Automotive Industry

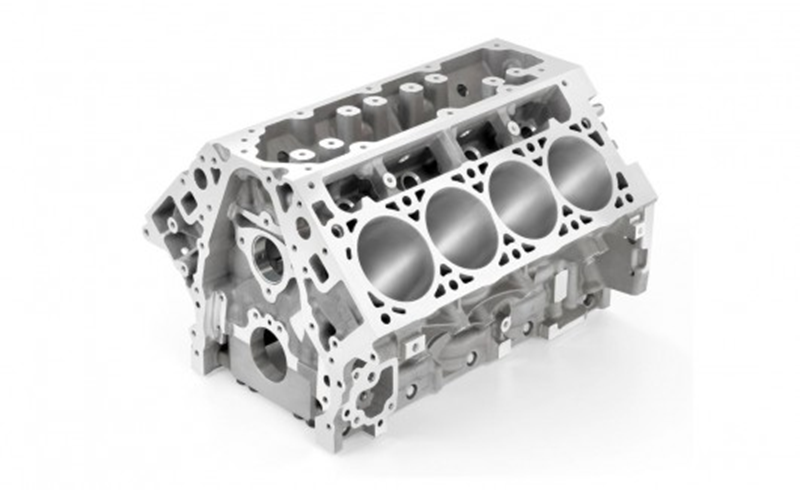

Engine Block

The engine block is one of the core components of a car. The traditional cast iron block is heavy and is not suitable for the lightweight requirements of modern cars. Through the die-casting process, the aluminum alloy cylinder block can significantly reduce weight while maintaining strength. In addition, aluminum alloy has good thermal conductivity and can effectively dissipate heat and improve engine efficiency.

Gearbox Housing

The gearbox housing is subject to extreme mechanical stress, so its material must have high strength and good toughness. The die-casting machine can produce a high-precision gearbox housing in one molding, reducing welding points and seams, thereby improving its durability and anti-seismic performance.

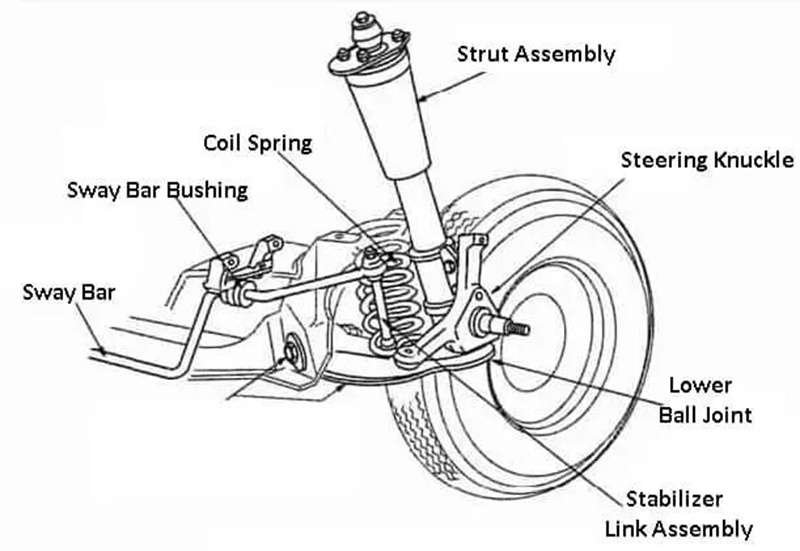

Suspension System Components

The suspension system is a key part of the vehicle's driving stability and comfort and requires components with high strength, durability, and lightweight. The die-casting process enables the production of complex aluminum alloy suspension system parts, with precise mold design ensuring functionality and structural integrity.

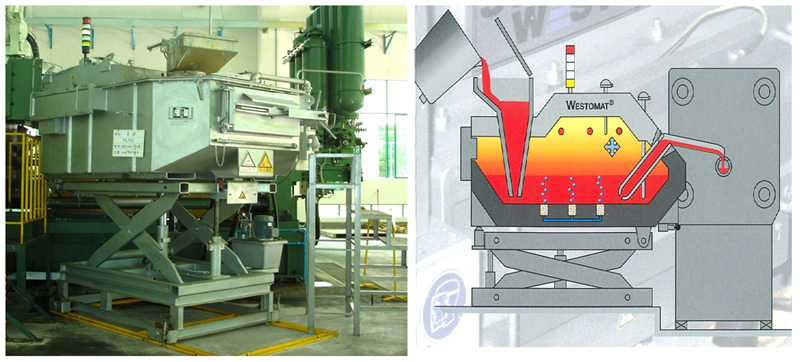

Mechanical Automation And Intelligent Manufacturing of ZAZ Group

In the process of Industry 4.0, die-casting machine technology is moving towards automation and intelligence. Our die-casting production line integrates robotic automation operation, a real-time monitoring system, and intelligent data analysis tools to automatically adjust production parameters and further improve production efficiency and product quality. For example, our quantitative furnace can not only keep the solution warm but also complete quantitative pouring.

ZAZ's Green Concept

While optimizing and upgrading die-casting machine technology, we continue to pay attention to environmental protection and sustainable development. By reducing energy consumption, optimizing material use, and recycling, the die-casting process will make the manufacturing process greener. For example, our die-casting machine can reduce the waste and energy consumption of metal materials through waste recovery systems and energy-saving technologies, thereby reducing its impact on the environment.

We are also committed to providing the most cost-effective die-casting machine procurement solutions for Middle Eastern customers. Our team has a deep understanding of the Middle East market, covering production environment, technical requirements, and industry standards, and can tailor precise solutions for customers to help them solve various problems in the procurement process, ensure equipment selection optimization, and achieve efficient production.

In addition, we have established a complete after-sales service system. Because of the efficient production and high-cost characteristics of die-casting equipment, we provide a full range of technical support. Whether it is during the equipment installation and commissioning stage or in daily operation, customers can contact our technical team by phone or online platform if they encounter any problems. We promise to respond quickly and provide professional technical solutions to ensure that customers' production lines are restored quickly, minimize downtime, and improve production efficiency.

If you have any needs for die-casting machines, accessories, and consumables, please contact us!

Learn more about our die-casting services through:

https://www.zazdiecasting.com/ and https://ae.zazdiecasting.com/

OTHER CONTENT

-

2024-09-19 14:16:15 LK Cold Chamber Die Casting Machine DCC900 Locking Force: 9000KN Die Height: 400-1000mm Space Between Tie Bars: 930x930mm Shot Weight: 13.5Kg Casting Area Max:2250c㎡

More -

2024-09-19 14:11:06 LK Cold Chamber Die Casting Machine DCC280 Locking Force: 2800KN Die Height: 250-650mm Space Between Tie Bars: 560x560mm Shot Weight: 2.9Kg Casting Area Max:700c㎡

More -

2024-09-19 10:23:07 LK Cold Chamber Die Casting Machine DCC580 Locking Force: 5000KN Die Heigh: 350-850mm Space Between Tie Bars: 760x760mm Shot Weight: 6.9Kg Casting Area Max:1250c㎡

More -

2024-09-19 10:11:20 LK Cold Chamber Die Casting Machine DCC400 Locking Force: 4000KN Die Height: 300-700mm Space Between Tie Bars: 669x669mm Shot Weight: 4.7Kg Casting Area Max:1000c㎡

More