How To Reduce Energy Consumption During The Use Of Die-casting Machines?

LK Die Casting Machine / 2024-11-15 16:15:38

The production efficiency and energy consumption of die-casting machines go hand in hand. Its energy consumption is multifaceted and has complex influencing factors. By optimizing the design and improving the production process, its energy consumption can be effectively reduced, and production efficiency and economic benefits can be improved.

Equipment Selection And Upgrade

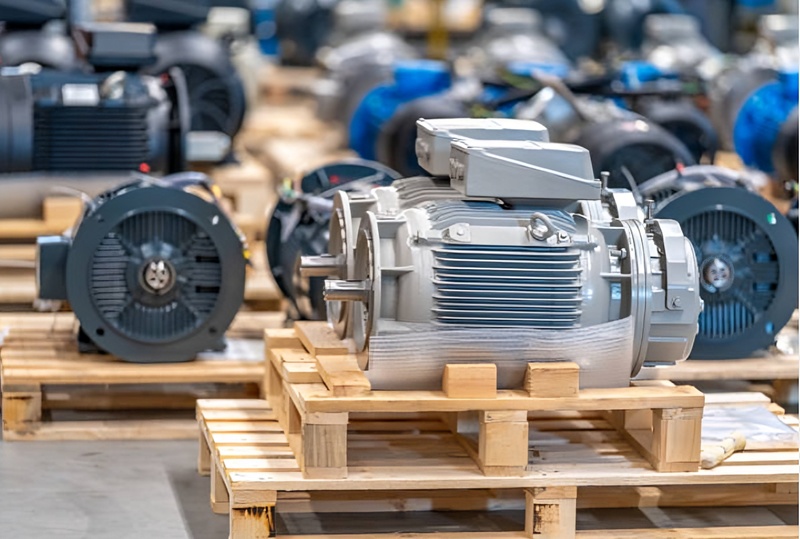

Select high-efficiency and energy-saving motors:

Select high-efficiency motors that meet national energy efficiency standards, which have higher energy conversion efficiency and can consume less electricity at the same output power. For example, permanent magnet synchronous motors are more efficient under partial load conditions than traditional asynchronous motors, which can effectively reduce energy consumption.

Equipped with Advanced Hydraulic Systems:

Select low-energy hydraulic pumps and motors, such as variable pumps and high-efficiency hydraulic motors. Variable pumps can automatically adjust the output flow and pressure according to the actual needs of the die-casting machine during operation, avoiding excess energy consumption; high-efficiency hydraulic motors have higher mechanical efficiency and lower energy loss.

Install Frequency Converters:

The frequency converter can automatically adjust the motor speed according to the load requirements of the die-casting machine at different working stages, so that the motor's output power matches the actual load, avoiding energy waste at low loads, and the power saving rate can reach 20%-60%.

Process Parameter Optimization

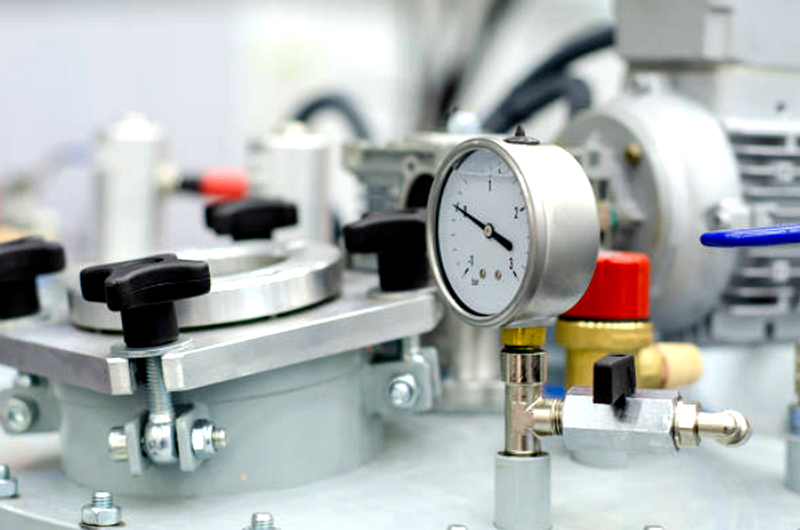

Reasonable Adjustment of Pressure Parameters:

On the premise of meeting the quality requirements of die-casting products, appropriately reduce the pressure in the die-casting process. Too high pressure will not only increase energy consumption but also cause excessive wear on molds and equipment. Through testing and analysis, find the best pressure value, which can not only ensure product quality but also reduce energy consumption.

Optimize Injection Speed:

Select the injection speed reasonably according to the shape, size, and process requirements of the product. Too fast injection speed will increase the energy consumption of the hydraulic system, while too slow injection speed may affect the molding quality of the product. By adjusting the injection speed, find a suitable balance point to reduce energy consumption.

Accurately Control Cooling Time:

Too long cooling time will increase energy consumption, while insufficient cooling time may affect product quality and production efficiency. Use advanced temperature monitoring equipment and control systems to monitor the temperature of molds and products in real-time, accurately control the cooling time according to actual conditions, and avoid unnecessary cooling energy consumption.

Equipment Maintenance And Management

Regularly maintain the hydraulic system:

Regularly check the sealing of the hydraulic system, repair the oil leakage points in time, and avoid hydraulic oil leakage. Leakage will not only cause waste of hydraulic oil but also cause the working pressure of the hydraulic system to drop so that the motor needs to consume more energy to maintain work. At the same time, replace the hydraulic oil and filter regularly to maintain the cleanliness of the hydraulic oil, reduce the friction resistance of the hydraulic system, and reduce energy consumption.

Keep the equipment clean:

Clean the surface and interior of the die-casting machine regularly to remove dust, oil stains, and debris. These impurities will affect the heat dissipation effect of the equipment, causing the equipment temperature to rise and increase energy consumption. Keeping the equipment clean can also extend the service life of the equipment and reduce the probability of failure.

Optimize the mold structure:

The structural design of the mold also affects the energy consumption of the die-casting machine. The use of a reasonable mold structure, such as optimizing the layout of the cooling water channel of the mold and reducing the weight of the mold, can reduce energy consumption during the die-casting process. In addition, regular maintenance and maintenance of the mold to ensure the accuracy and surface quality of the mold can also help reduce energy consumption.

Energy Recycling

Recover hydraulic energy:

During the operation of the die-casting machine, the hydraulic system will generate a lot of energy loss. An energy recovery device can be used to convert the pressure energy in the hydraulic system into electrical energy or other forms of energy for recycling. For example, the use of a hydraulic accumulator can store excess hydraulic energy during the operation of the die-casting machine and release it when needed to reduce the energy consumption of the motor.

Waste heat recovery:

A large amount of heat is generated during the die-casting process, especially during the heating and cooling of the mold. By installing a waste heat recovery device, this heat can be recovered and used in other links that require heating, such as workshop heating, hot water supply, etc., to improve energy utilization.

Operation And Training

Improve operator skills:

Strengthen the training of operators to improve their operating skills and energy-saving awareness. Operators should be familiar with the working principle and operation method of the die-casting machine, and be able to reasonably adjust the operating parameters of the equipment according to actual conditions to avoid energy waste caused by improper operation.

Develop reasonable operating procedures:

Establish perfect operating procedures to regulate the behavior of operators. For example, when starting and stopping the equipment, operate in the prescribed order to avoid frequent start and stop; when the equipment is idle, turn off unnecessary functions such as lighting and heating in time.

The energy consumption of die-casting machines is quite large, so equipping them with efficient equipment, energy-saving systems, auxiliary supporting technologies, and correct operating procedures is essential for energy-saving and efficiency-enhancing.

Want to know more specific information about the die-casting machines? Click the "Contact" button and get in touch with us!

OTHER CONTENT

-

2024-09-19 14:16:15 LK Cold Chamber Die Casting Machine DCC900 Locking Force: 9000KN Die Height: 400-1000mm Space Between Tie Bars: 930x930mm Shot Weight: 13.5Kg Casting Area Max:2250c㎡

More -

2024-09-19 14:11:06 LK Cold Chamber Die Casting Machine DCC280 Locking Force: 2800KN Die Height: 250-650mm Space Between Tie Bars: 560x560mm Shot Weight: 2.9Kg Casting Area Max:700c㎡

More -

2024-09-19 10:23:07 LK Cold Chamber Die Casting Machine DCC580 Locking Force: 5000KN Die Heigh: 350-850mm Space Between Tie Bars: 760x760mm Shot Weight: 6.9Kg Casting Area Max:1250c㎡

More -

2024-09-19 10:11:20 LK Cold Chamber Die Casting Machine DCC400 Locking Force: 4000KN Die Height: 300-700mm Space Between Tie Bars: 669x669mm Shot Weight: 4.7Kg Casting Area Max:1000c㎡

More