How to Choose The Best Die-casting Machine Model According to Casting Needs?

LK Die Casting Machine / 2024-11-21 10:43:40

Die-casting technology is a metal casting process widely used in the automotive, electronics, aviation, home appliances, and other industries. From tiny, precision parts to large, complex castings, choosing the right die-casting machine model is crucial to ensure casting quality and production efficiency.

This article will explore in depth how to help you choose the most suitable die-casting machine according to the size, complexity, and material requirements of the casting.

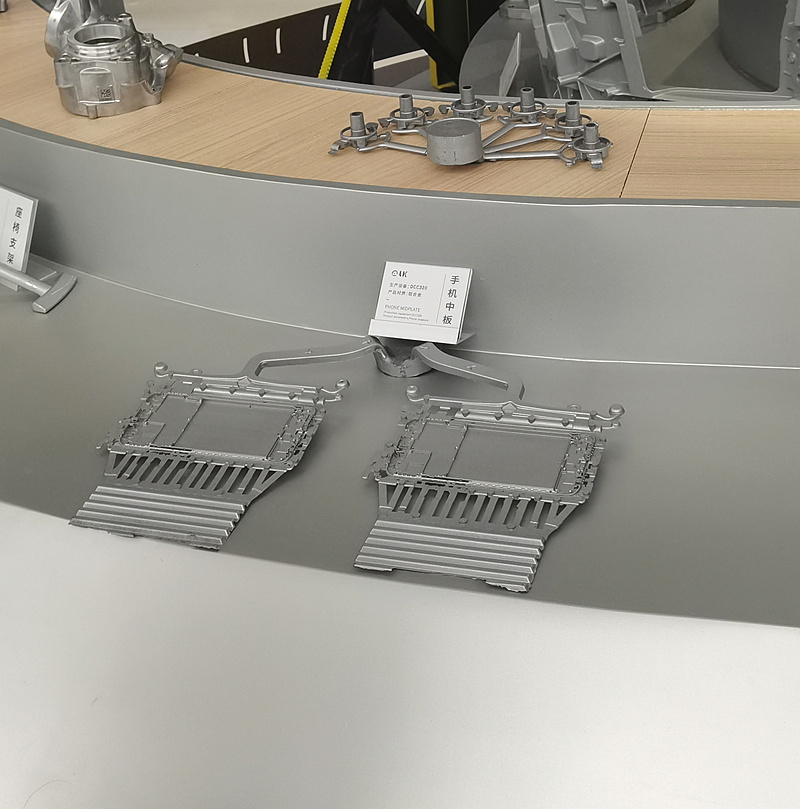

( Our Die-casting Machine Casting Products: from tiny, precision parts to large, complex castings)

1. Basic Principles of Die-casting Machines

The working principle of die-casting machines is to inject molten metal into the mold and solidify it under high pressure to form the required casting.

The main processes include:

Metal smelting and injection: The metal material is heated to a liquid state and injected into the mold cavity at high speed through the injection system.

Pressure effect: The high pressure applied during the injection process ensures the density and precision of the casting.

Cooling and molding: The molten metal is cooled and solidified in the mold, and then de-mold and post-processed after molding.

According to these principles, die-casting machines can be divided into hot-chamber die-casting machines and cold-chamber die-casting machines. Hot chamber die-casting machines are suitable for low melting point metals (such as zinc and aluminum), while cold chamber die-casting machines are often used for high melting point metals (such as aluminum alloys and magnesium alloys).

2. Characteristics of Different Types of Die-casting Machines

Small Die-casting Machines:

Suitable for the production of fine small parts, such as mobile phone housings, TV housings, car lampshades, etc. The characteristics of small die-casting machines include:

High production accuracy: Can produce small and complex castings, such as electronic product housings, connectors, buttons, etc.

Applicable materials: Mainly suitable for light metals such as aluminum and zinc, and can produce small and thin-walled castings.

Fast injection speed: Small die-casting machines generally have faster injection speeds and are suitable for efficient production.

(Mobile phone mid-board)

Medium Die-casting Machines:

Suitable for the production of medium-sized and complex castings, such as automotive accessories, home appliance parts, tool housings, etc. The characteristics of medium-sized die-casting machines are:

Moderate injection pressure: Can cope with larger-sized and complex-structured castings.

Higher production efficiency: Provides higher output in batch production, suitable for large-scale production.

Applicable to a variety of materials: In addition to aluminum alloys, it can also process lighter metal materials such as magnesium alloys.

(Motorcycle parts housing)

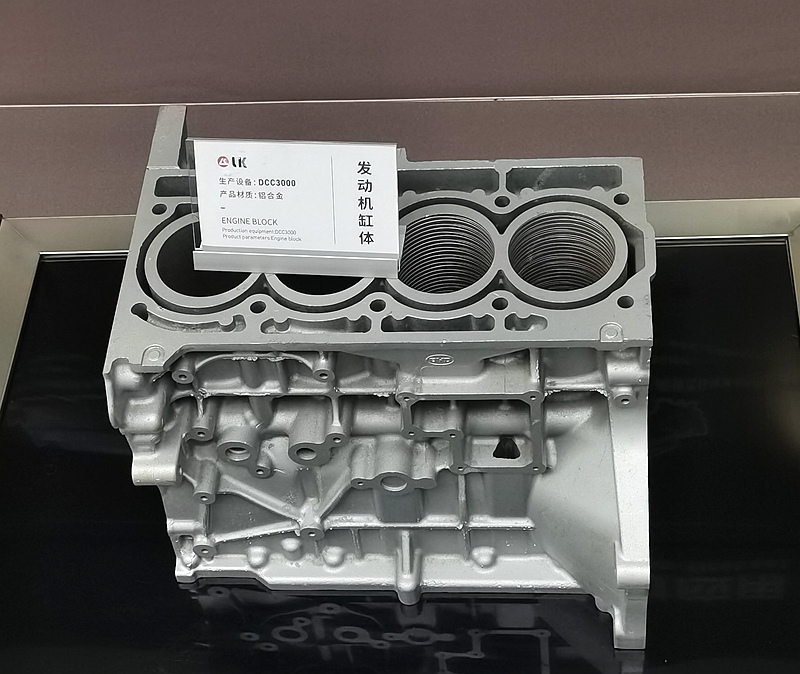

Large Die-casting Machine:

Mainly used to produce large-sized and heavy castings, such as automobile engine housings, aluminum alloy wheels, heavy machinery parts, etc. Its features include:

High-pressure system: Able to withstand greater injection pressure, suitable for the production of large and complex castings, such as engine housings and automobile wheels.

Strong high-temperature resistance: Mostly used for casting of high melting point metals, such as aluminum, magnesium alloys, etc.

Longer cooling time: For large castings, the cooling and molding time is longer, but the strength and stability of the castings are guaranteed.

(Engine block)

3. Requirements And Selection of Different Castings

Precision Requirements:

For castings that require high precision (such as electronic components and precision instrument parts), it is necessary to select a die-casting machine that can provide delicate injection and precise control. For example, a small or medium-sized die-casting machine can meet the precision requirements, while a large die-casting machine may not be suitable for such high-precision production due to the high injection pressure.

Material type:

Different die-casting machines are suitable for different metal materials:

Aluminum alloy: Commonly used in medium and large die-casting machines, used for automotive parts, electronic housings, etc.

Zinc alloy: Commonly used in small die-casting machines, suitable for the production of small and complex castings.

Magnesium alloy: A lighter metal, often used for lightweight automotive parts, suitable for medium and larger die-casting machines.

Complexity of castings:

For castings with complex structures and large sizes (such as automobile engine housings and large frames of mechanical equipment), it is necessary to select a large die-casting machine because it can provide stronger pressure and larger mold space to adapt to the molding of complex castings.

Production volume and efficiency:

The selection of die-casting machines also needs to consider the quantity and cycle of production. If the production volume is large, you can choose a high-efficiency medium or large die-casting machine, while for precision and low-volume castings, you can choose a small die-casting machine for precision production.

4. How to Choose A Die-casting Machine Model According to Casting Requirements?

When choosing a die-casting machine, you need to consider the following factors:

The size and weight of the casting: Small parts use a small die-casting machine; large-sized and heavy castings use a large die-casting machine.

The shape and complexity of the casting: For castings with complex shapes, such as parts that require precise details, choose a small or medium-sized die-casting machine that can provide precise control.

Production speed and batch: For high-speed and large-volume production, choose a medium or large die-casting machine with high production efficiency.

Material type: It is necessary to consider whether the die-casting machine is compatible with the selected metal material, such as aluminum alloy, zinc alloy, or magnesium alloy.

5. Summary And Suggestions

Choosing a suitable die-casting machine model is the key to ensuring casting quality and production efficiency. Through a comprehensive analysis of the size, complexity, material requirements, etc. of the casting, choosing a suitable die-casting machine can improve production efficiency while ensuring product accuracy and quality. Different models of die-casting machines have their advantages under different production needs. Knowing how to select models according to specific needs will help companies improve production efficiency, reduce costs, and enhance market competitiveness.

Hope this article resolves your selection issues. If you want to know more information about our die-casting machines, please contact us or send us an e-mail. For more die-casting machine knowledge, please browse the Blog on our website.

OTHER CONTENT

-

2024-09-19 14:16:15 LK Cold Chamber Die Casting Machine DCC900 Locking Force: 9000KN Die Height: 400-1000mm Space Between Tie Bars: 930x930mm Shot Weight: 13.5Kg Casting Area Max:2250c㎡

More -

2024-09-19 14:11:06 LK Cold Chamber Die Casting Machine DCC280 Locking Force: 2800KN Die Height: 250-650mm Space Between Tie Bars: 560x560mm Shot Weight: 2.9Kg Casting Area Max:700c㎡

More -

2024-09-19 10:23:07 LK Cold Chamber Die Casting Machine DCC580 Locking Force: 5000KN Die Heigh: 350-850mm Space Between Tie Bars: 760x760mm Shot Weight: 6.9Kg Casting Area Max:1250c㎡

More -

2024-09-19 10:11:20 LK Cold Chamber Die Casting Machine DCC400 Locking Force: 4000KN Die Height: 300-700mm Space Between Tie Bars: 669x669mm Shot Weight: 4.7Kg Casting Area Max:1000c㎡

More