From Delivery to Production: Turnkey Die Casting Machine Installation & Commissioning

LK Die Casting Machine / 2025-08-06 15:57:21

When investing in a new die casting machine, installation and commissioning are just as critical as the machine itself. At ZAZ Group, we go beyond selling equipment — we ensure that your entire production line is properly installed, safely commissioned, and ready to perform from day one.

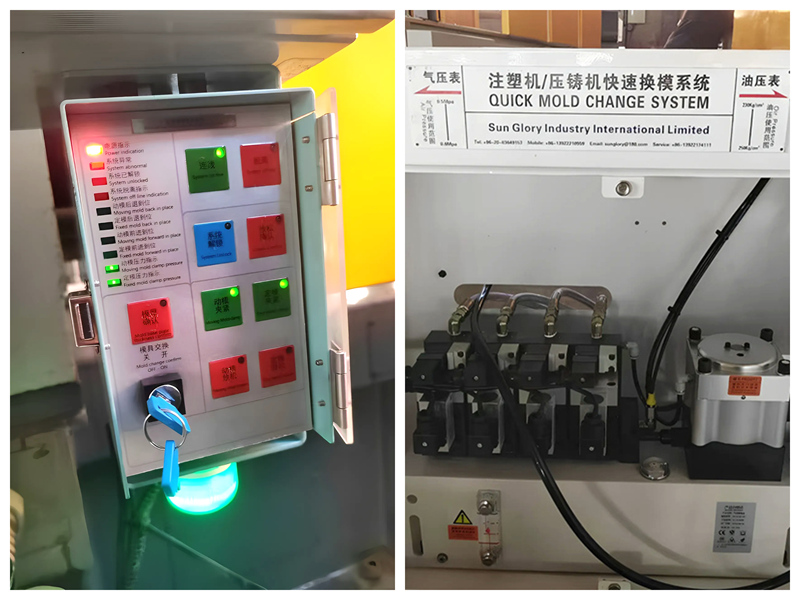

Our recent project showcases this commitment. The customer purchased a complete die casting machine from us, and we were responsible for the installation and debugging of not only the machine itself but also the integrated equipment, including the melting furnace, quick die change (QDC) system, and other automation components.

What We Provide: Complete On-Site Installation

Our technical service team handles every step of the die casting machine installation process:

1) Mechanical Assembly

Assembling the main body of the die casting machine with precise alignment

2) Electrical & Control Integration

Power connections, PLC and HMI integration, safety wiring

3) Peripheral Equipment Setup

Setup of key auxiliary equipment, including:

-- Melting & holding furnaces

-- Automatic ladlers and extractors

-- Quick Die Change (QDC) system

-- Hydraulic units & cooling systems

-- Utility Connections

-- Hydraulic lines, compressed air, cooling water, and exhaust piping

Commissioning & Debugging

After installation, we perform complete die casting machine commissioning, including:

1) Initial system startup and safety verification

2) Parameter configuration (injection speed, pressure, cycle time)

3) Communication testing across PLC, robot arms, and peripheral systems

4) Production of test castings for functionality and quality assurance

Comprehensive Support to Maximize Your Machine Performance

To ensure your equipment runs efficiently and your team operates with confidence, we offer a complete range of operator training and technical support services.

We provide:

-- On-site training for machine operators and technicians

-- Maintenance and troubleshooting guidance

-- Remote support options

-- Spare parts supply and long-term technical support

Smooth Start-Up, Zero Downtime

Thanks to our experienced team and standardized installation workflow, our customer successfully launched production with minimal delays. We’re proud to deliver not only machines but complete turnkey die casting solutions.

Need Help With Installation?

If you're planning to expand or upgrade your die casting operation, contact us today. We'll provide the equipment and the expertise.

OTHER CONTENT

-

2024-09-19 14:16:15 LK Cold Chamber Die Casting Machine DCC900 Locking Force: 9000KN Die Height: 400-1000mm Space Between Tie Bars: 930x930mm Shot Weight: 13.5Kg Casting Area Max:2250c㎡

More -

2024-09-19 14:11:06 LK Cold Chamber Die Casting Machine DCC280 Locking Force: 2800KN Die Height: 250-650mm Space Between Tie Bars: 560x560mm Shot Weight: 2.9Kg Casting Area Max:700c㎡

More -

2024-09-19 10:23:07 LK Cold Chamber Die Casting Machine DCC580 Locking Force: 5000KN Die Heigh: 350-850mm Space Between Tie Bars: 760x760mm Shot Weight: 6.9Kg Casting Area Max:1250c㎡

More -

2024-09-19 10:11:20 LK Cold Chamber Die Casting Machine DCC400 Locking Force: 4000KN Die Height: 300-700mm Space Between Tie Bars: 669x669mm Shot Weight: 4.7Kg Casting Area Max:1000c㎡

More