The Power of Magnesium Alloy Die Casting in the Lightweight Revolution

LK Die Casting Machine / 2025-05-20 15:39:14

Against the background of the continuous deepening of the global carbon neutrality strategy, the lightweight of new energy vehicles has become an important development direction of the automobile industry. Magnesium alloy, as the lightest metal structural material known so far, is rapidly becoming a key breakthrough for the transformation of mainstream global auto companies. The high-performance magnesium alloy die-casting machine we provide is the ideal weapon for Middle Eastern manufacturing companies to enter this wave of industrial upgrading.

(Our die casting machines are running smoothly in our Egyptian customer's factory)

Global Trend: Magnesium Alloy Leads the Next Generation of Automotive Material Revolution

The density of magnesium alloy is only 1/4 of steel and 2/3 of aluminum, but it has high specific strength, excellent damping and shock absorption performance, and excellent electromagnetic shielding ability. Especially after the breakthrough in superplastic forming technology, magnesium alloy can now be competitive for more complex and high-strength automotive parts, such as steering brackets, instrument panel frames, seat frames, battery pack shells, motor end covers, etc.

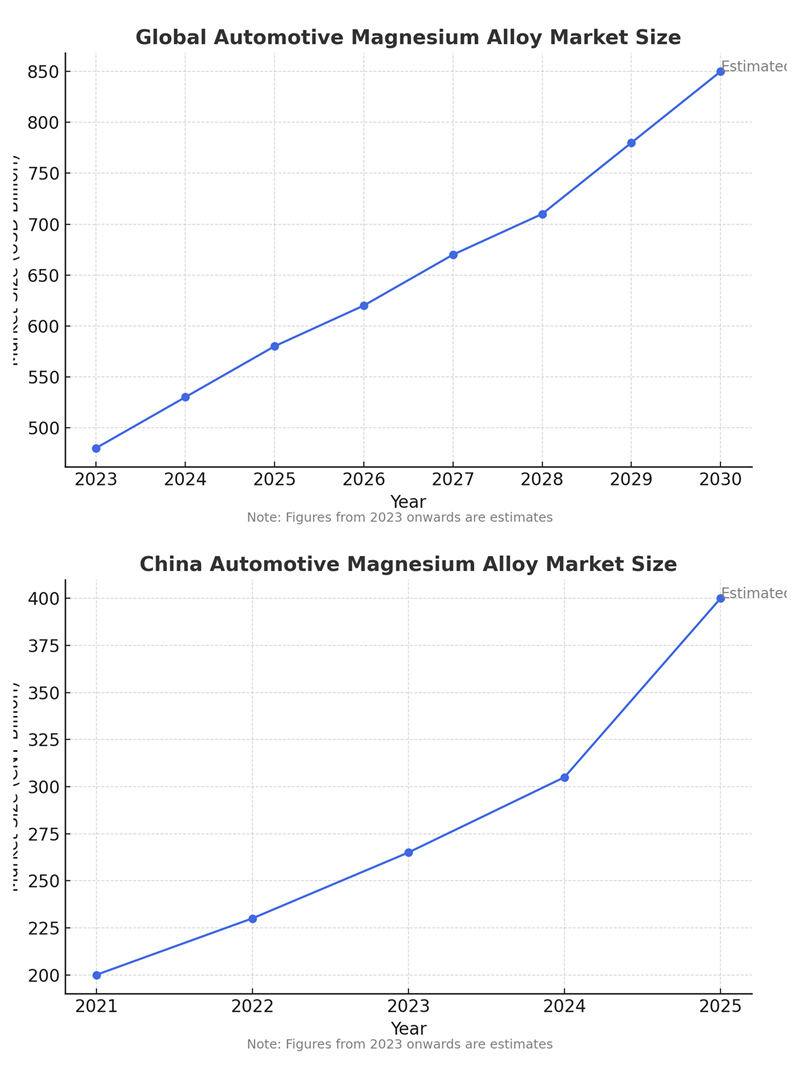

According to data from CITIC Securities Research Institute, China's automotive magnesium alloy market will exceed 40 billion yuan in 2025, with a compound annual growth rate of 15%, far higher than the global average growth rate of 7%. In the international market, the global market size is expected to reach 85 billion US dollars by 2030, and Europe has taken the lead in using magnesium alloys for a variety of new energy vehicle models.

Middle East Perspective: Huge Potential of New Energy Vehicles + Local Manufacturing

The Middle East is gradually promoting green energy transformation, and many countries have issued policies to support the localization of the new energy vehicle industry chain:

-- Saudi Arabia's Vision 2030 strategy proposes to promote the upgrading of local manufacturing and introduce new energy vehicle production lines.

-- The UAE Green Economy Initiative plans to achieve a sales share of more than 30% of new energy vehicles by 2030.

-- Egypt is also actively promoting local automobile manufacturing and announced the launch of its first local electric vehicle production project in 2024.

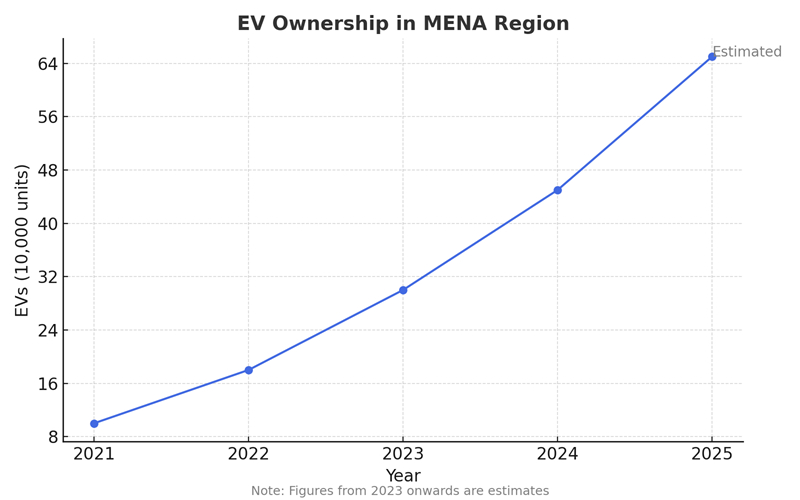

According to data released by the GCC Statistics Center, by the end of 2023, the annual growth rate of new energy vehicle registrations in Gulf countries will exceed 35%, and it is expected that the number of new energy vehicles in the Middle East will exceed 2.5 million by 2030. This means that the demand for lightweight materials, especially magnesium alloy parts, will rise rapidly.

However, the Middle East is still relatively untapped in the field of magnesium alloy die-casting. Most of it relies on imports, which have long delivery times and high costs, which limit the speed of its industrial upgrading.

⚙ Our Die-casting Solutions: Tailored for the Middle East Market

As a leading die-casting equipment manufacturer, our magnesium alloy die-casting machines have the following advantages:

✅ Special high-temperature alloy system for magnesium alloys

In view of the flammability of magnesium, our die-casting machines are equipped with intelligent high-temperature alloy furnaces featuring precise temperature control and automatic adjustment. Combined with a spray cooling system, this ensures both operational safety and consistent product quality.

✅ High-pressure fast clamping system

Adapts to complex component structures, improves mold life and molding accuracy, and supports mass production of new energy vehicle structural parts.

✅ Modular configuration, supports customization

Suitable for small and medium-sized manufacturing companies in the Middle East market to gradually expand production capacity and reduce initial investment risks.

✅ Remote operation and training support

Cooperate with our parts warehouse and local service team in Egypt to provide fast after-sales and regular training to ensure stable production for customers.

(Our die casting consumables warehouse and professional engineers in Egypt)

Cooperation Prospects: Golden Window for Magnesium Alloy Parts Manufacturing in the Middle East

--For existing automotive parts suppliers, upgrading die-casting equipment and introducing magnesium alloy production lines can help enter the core supply chain of new energy vehicles.

--For Middle Eastern industrial manufacturers: Seize the global trend of material substitution and build a lightweight industrial foundation for the future.

--For governments and investment institutions: Localized magnesium alloy die-casting will effectively fill the technical gap and drive the growth of the upstream and downstream manufacturing ecology.

Practical & Professional

We supply die-casting machines designed for magnesium alloys, helping manufacturers in the Middle East move toward lightweight production.

As LK Group’s official agent in Egypt, we provide fast local service, on-site installation, and technical training – so you can focus on production, not troubleshooting.

Contact us today to get a tailored machine solution and quote!

OTHER CONTENT

-

2024-09-19 14:16:15 LK Cold Chamber Die Casting Machine DCC900 Locking Force: 9000KN Die Height: 400-1000mm Space Between Tie Bars: 930x930mm Shot Weight: 13.5Kg Casting Area Max:2250c㎡

More -

2024-09-19 14:11:06 LK Cold Chamber Die Casting Machine DCC280 Locking Force: 2800KN Die Height: 250-650mm Space Between Tie Bars: 560x560mm Shot Weight: 2.9Kg Casting Area Max:700c㎡

More -

2024-09-19 10:23:07 LK Cold Chamber Die Casting Machine DCC580 Locking Force: 5000KN Die Heigh: 350-850mm Space Between Tie Bars: 760x760mm Shot Weight: 6.9Kg Casting Area Max:1250c㎡

More -

2024-09-19 10:11:20 LK Cold Chamber Die Casting Machine DCC400 Locking Force: 4000KN Die Height: 300-700mm Space Between Tie Bars: 669x669mm Shot Weight: 4.7Kg Casting Area Max:1000c㎡

More