Cutting-edge technology and innovations for aggregates production

-

ZAZ--China Die Casting Machine Distributor, Providing Customers With Integrated Services

In today's manufacturing industry booming era, die casting process as an important metal molding method, in many fields play a key role. ZAZ Group as China's die-casting machine distributor, we shoulder connecting quality die casting machine manufacturers (LKGroup) and the majority of...

READ MORE -

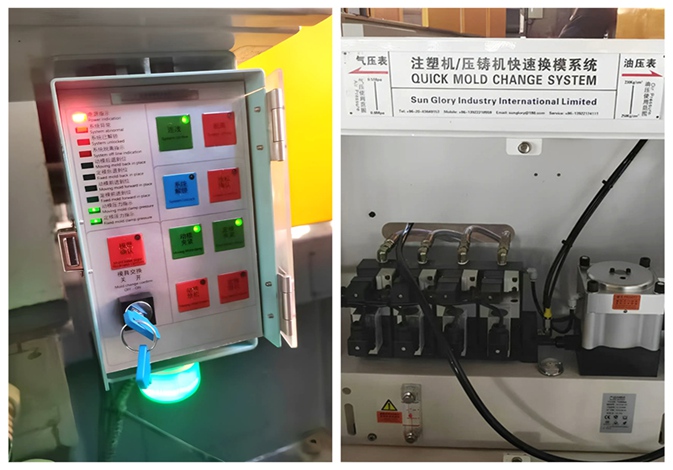

From Delivery to Production: Turnkey Die Casting Machine Installation & Commissioning

Need expert die casting machine installation? We offer complete setup and commissioning services for die casting machines, furnaces, and QDC systems. Fast and reliable....

READ MORE -

The Power of Magnesium Alloy Die Casting in the Lightweight Revolution

Discover how our die casting machines support the growing use of magnesium alloys in the lightweight automobile industry, with strong potential in the booming Middle East market....

READ MORE -

Challenges and Countermeasures for Die-casting Machine Operation in the High-Temperature Environment

Our high-performance die-casting machines are specially engineered to withstand the extreme heat of Middle Eastern climates, ensuring stable and efficient operation even under high ambient temperatures....

READ MORE -

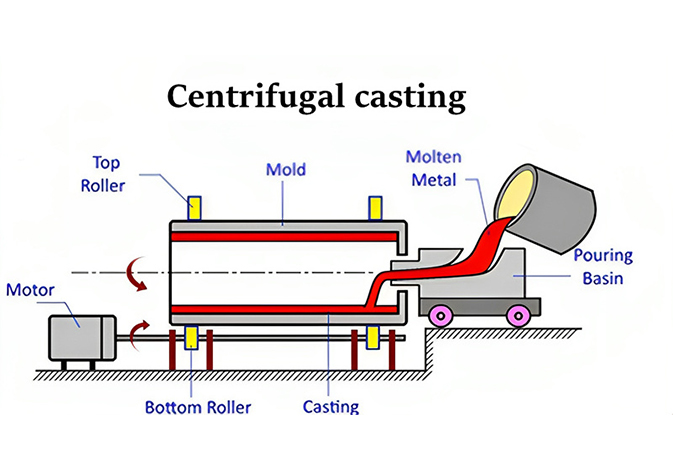

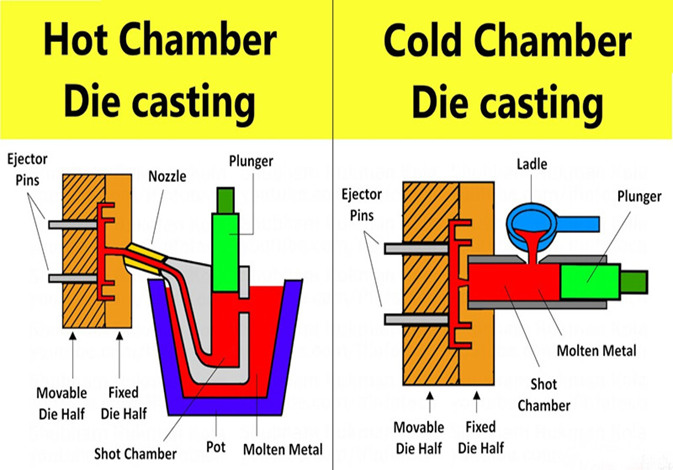

Differences Between Die Casting And Centrifugal Casting

Die casting and centrifugal casting are both casting processes, but they differ significantly in terms of their process characteristics and application areas. Each process plays a crucial role in the casting industry, and understanding their distinctions is essential for selecting the appropriate me...

READ MORE -

How Die Casting and Anodizing Give Aluminum Nonstick Cookware Color And Durability?

Aluminum nonstick pots have many advantages such as lightness, good thermal conductivity, and corrosion resistance, and are widely used in the kitchen. Today, let’s uncover the mysterious process from metal aluminum to non-stick pots....

READ MORE -

How Does An Aluminum Die-casting Machine Create Perfect Pots?

As the official agent of LK die-casting machines in Egypt, we provide our customers with the highest quality aluminum die-casting machines and one-stop services from transportation to installation. We have all types of die-casting machines for you to choose from. If you are interested, please feel free to contact us....

READ MORE -

Some Measures You Might Need To Solve Problems During The Die-casting Machine Production

Die-casting machines are mechanical equipment that obtain metal castings by injecting molten metal (such as aluminum, zinc, magnesium, etc.) into the mold cavity under high pressure and cooling and solidifying it. They are the core equipment of the die-casting process. This article will provide you...

READ MORE -

About the Die Casting Release Agent (the mold release lubricant)

The die-casting release agentis a chemical substance used in the metal die-casting process. Its main function is to prevent the adhesion between the casting and the mold and help the casting to be smoothly released from the mold, thereby reducing wear, improving production efficiency, and ensu...

READ MORE -

Die Casting Machine Adaptation Guide: Comparison of Aluminum And Zinc Alloy Solution Die Casting Pro

No matter aluminum die-casting machines or zinc die-casting machineshave their own advantages. Choosing a suitable die-casting machine according to production needs can improve production efficiency and maximize the utilization of metal solutions....

READ MORE -

How the Aluminum Pressure Die Casting Machine Works for the Aluminum Die Cast Cookware?

Aluminum pressure die casting is widely used in manufacturing aluminum die-cast cookware, like frying pans, pots, and lids, due to its ability to produce precise, durable, and lightweight parts with excellent surface finish. If you need machines to produce cookware like pots, and pans, come to contact us, and we will recommend the most suitable machine....

READ MORE -

Die-casting Mold: One Mold Produces Six Parts!

A die-casting mold is a crucial part of the die-casting process, used to shape molten metal into specific, pre-designed parts....

READ MORE