Cutting-edge technology and innovations for aggregates production

-

How to Choose The Best Die-casting Machine Model According to Casting Needs?

Die-casting technology is a metal casting process widely used in the automotive, electronics, aviation, home appliances, and other industries. From tiny, precision parts to large, complex castings, choosing the right die-casting machine model is crucial to ensure casting quality and production effic...

READ MORE -

Energy Consumption of Die-casting Machine

The energy consumption of a die-casting machine is mainly affected by many factors such as its working principle, equipment type, production process, and production scale. The die-casting machine is usually used for high-speed casting of metals such as aluminum, zinc, and magnesium, and its en...

READ MORE -

How To Reduce Energy Consumption During The Use Of Die-casting Machines?

The production efficiency and energy consumption of die-casting machines go hand in hand. Its energy consumption is multifaceted and has complex influencing factors. By optimizing the design and improving the production process, its energy consumption can be effectively reduced, and production effic...

READ MORE -

Die Casting Machine Purchasing Decision: New or Used? Which is Better for Your Business?

As we all know, in the process of technology, a large number of die-casting machines have been put into the process of industrial production, which has greatly improved the production efficiency and quality of the factory. While greatly reducing the manufacturing cost and also being more envir...

READ MORE -

Choose China Die Casting Machine: Provide You With an Efficient, Economical, and Reliable Solution

According to the latest Chinese customs data, from January to September 2024, China exported 505 cold die-casting machines. In the process of global science and technology, China's manufacturing industry has developed rapidly with the government's strong support and the demand of the worldwi...

READ MORE -

How to Choose the Right Alloy Solution Used for Die Casting Molds?

Alloy solutionis the raw material for die castings. Die-casting machines need to use different molds to make castings. The process is to inject alloy solution into the mold under high pressure and wait for it to cool and solidify into the desired shape. The quality of the alloy solution is the...

READ MORE -

The future of magnesium alloys - bringing technological innovation in the field of die-casting

The future of magnesium alloys:Leading a new era of lightweight, bringing technological innovation and market opportunities in the field of die-casting.Magnesium alloys are magnesium-based alloys, which are usually improved by adding other metals (such as aluminum, zinc, manganese, silicon, copper,...

READ MORE -

Hot and Cold Chamber Die Casting Difference

Die casting is a common and important process in the foundry industry. Die casting is divided into hot chamber die casting and cold chamber die casting, which significantly differ in equipment, process, and application....

READ MORE -

Application of Die Casting Machines In The Automotive Industry

2024-10-23 by DawnThe automotive industry occupies an important position in the global economy. With the increasing trend of electrification, lightweight and intelligence, the production process of automotive parts is constantly optimized. In this context, die-casting machineshave become an in...

READ MORE -

Belt Drive Blower

2024-10-18 by Cherry In modern manufacturing, die-casting machines, as core equipment, are widely used in many industries such as automobiles, aerospace, electronics, and home appliances to produce high-precision and complex-shaped metal parts. With the continuous advancement of industry technology, the efficiency...

READ MORE -

High Speed Inline Palletizer

2024-10-17 by Cherry High-Speed Inline Palletizer2024-10-17 by CherryIn modern manufacturing, die-casting machines have become one of the key equipment and are widely used in many fields such as automobiles, aerospace, consumer electronics, etc. to produce various precision metal parts. With the growing production...

READ MORE -

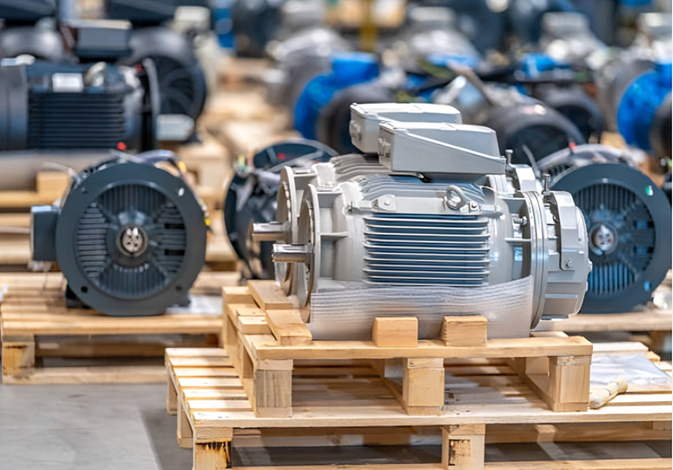

Stator Diagram

2024-10-16 by Cherry Stator Diagram2024-10-16 by CherryIntroductionIn modern industrial production, the die casting machine, as an important metal forming equipment, is widely used to produce various complex shapes and high-precision metal parts. It is used in many fields such as automobiles, electronics, aerospace, e...

READ MORE