We provide comprehensive consultation and support for all die casting machine-related inquiries, offering professional services, technical expertise, and reliable solutions.

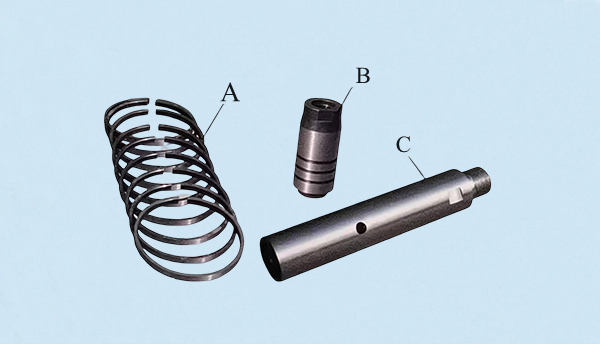

Piston Ring(A), Piston Head(B), Piston Rod(C)

These three parts are important accessories commonly used in hot die-casting machines. They are made of high-strength steel that is resistant to high temperatures and wear and use vacuum high-pressure gas quenching to uniform the hardness. The specifications can be customized and perfectly adapted to all types of die-casting machines.Gooseneck Thermocouple & Furnace Thermocouple

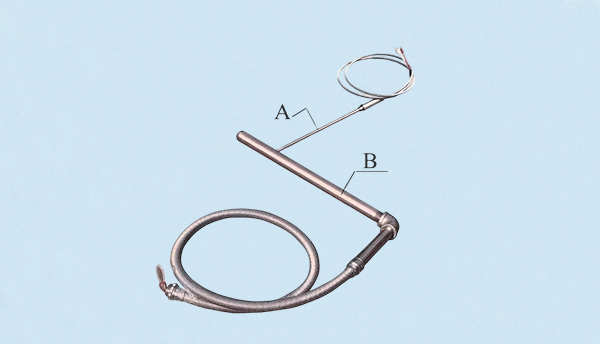

Both gooseneck thermocouple(A) and furnace thermocouple(B) measure temperature through direct contact, ensuring high accuracy with minimal error. Their outer protective tube sleeves are made of stainless steel, which is resistant to corrosion by molten alloy, and their inner parts are made of insulating porcelain tube material with good insulation performance.Hot Chamber Die Casting Nozzle Body

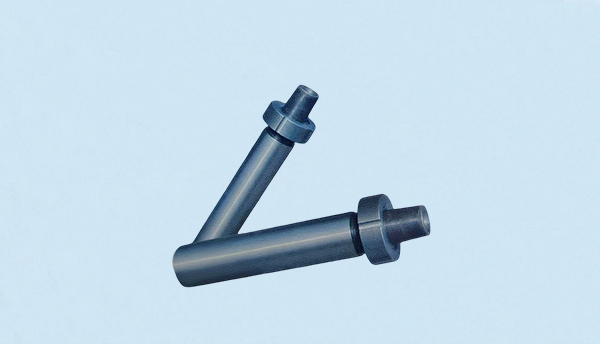

The nozzle body is used with the nozzle head to transport molten metal into the mold cavity. Our nozzle body is made of high-quality steel, processed by CNC machine tools, and heat-treated industrially, with more accurate dimensional accuracy and longer service life.Hot Chamber Die Casting Nozzle Head

The nozzle head is a key component that connects the injection system and the mold in a hot die-casting machine. It is mainly used to transport the molten metal from the injection chamber to the mold cavity. Our nozzle head is made of high-quality steel and is treated with vacuum high-pressure gas quenching to ensure uniform hardness. It can be disassembled for use.Hot Chamber Die Casting Gooseneck

Hot chamber die casting gooseneck is mainly composed of a hopper and a bush pot. Our gooseneck is made of cast iron and heat-resistant alloy, and with a fine heat treatment process, it has good density and wear resistance, is strong and durable, and has a long service life.Metal Melting Crucible

Our melting metal crucibles are made of cast iron with high-temperature resistant ceramic coating. It has good heat resistance, and oxidation resistance, and at a lower cost.Nozzle Heater、Heating Disc、Heating Rod

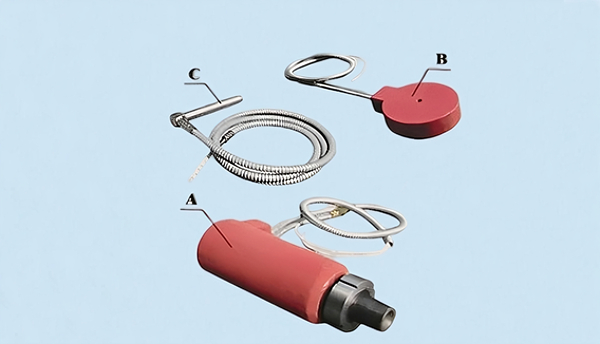

A: Nozzle Heater B: Heating Disc C: Heating Rod These three parts represent the nozzle heater, heating disc, and heating rod. They are used to maintain and control the temperature of the melting metal during the hot chamber die casting machine's working process.Refining Agent/ Deslagging Agent

The refining agent can separate the aluminum and decompose the aluminum oxide in the slag. By using the refining agent, the slag will become quite dry and loose, with very little aluminum mixed. After treatment, the purity of the aluminum liquid is greatly improved, the alloy performance is improved, and the aluminum consumption is reduced.LK Cold Chamber Die Casting Machine DCC900

Locking Force: 9000KN Die Height: 400-1000mm Space Between Tie Bars: 930x930mm Shot Weight: 13.5Kg Casting Area Max:2250c㎡LK Cold Chamber Die Casting Machine DCC280

Locking Force: 2800KN Die Height: 250-650mm Space Between Tie Bars: 560x560mm Shot Weight: 2.9Kg Casting Area Max:700c㎡LK Cold Chamber Die Casting Machine DCC580

Locking Force: 5000KN Die Heigh: 350-850mm Space Between Tie Bars: 760x760mm Shot Weight: 6.9Kg Casting Area Max:1250c㎡LK Cold Chamber Die Casting Machine DCC400

Locking Force: 4000KN Die Height: 300-700mm Space Between Tie Bars: 669x669mm Shot Weight: 4.7Kg Casting Area Max:1000c㎡

SIGN UP FOR OUR NEWSLETTER