We provide comprehensive consultation and support for all die casting machine-related inquiries, offering professional services, technical expertise, and reliable solutions.

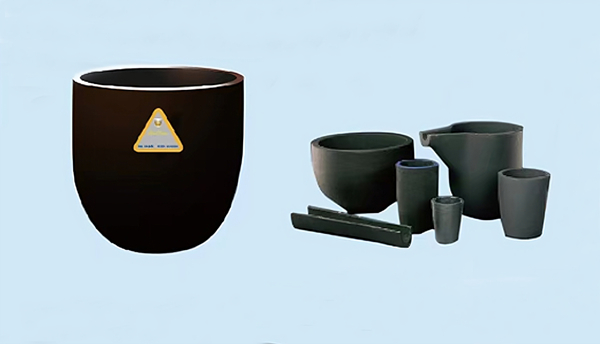

Silicon Carbide Graphite Crucible

A silicon carbide graphite crucible is a container used for high-temperature smelting. It is mainly composed of two materials: graphite and silicon carbide. It combines the good thermal conductivity of graphite with the high hardness, high strength, and excellent chemical stability of silicon carbide.Plunger Connector/ Plunger Adapter

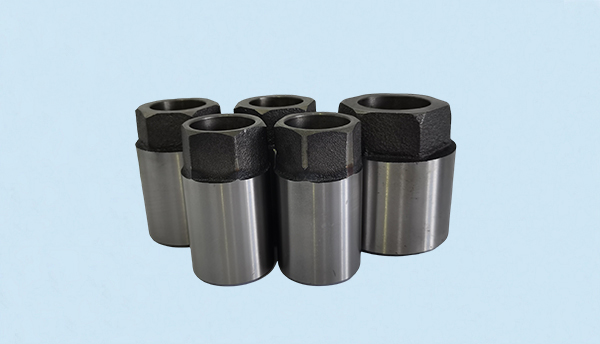

The plunger connector is a connecting part used to connect the injection system and the injection rod in the die-casting machine. It is responsible for ensuring the reliable connection between the injection rod and other mechanical parts and transmitting mechanical force.Coating Agent

The coating agent is a silver-grey paste and is used on the surface of containers that come into contact with non-ferrous metal solutions, such as cast iron crucibles, slag ladles, aluminum buckets, etc. It forms a high-temperature-resistant layer that can extend the life of the container and isolate the contamination and penetration of iron impurities into the alloy solution.Plunger lubricant oil

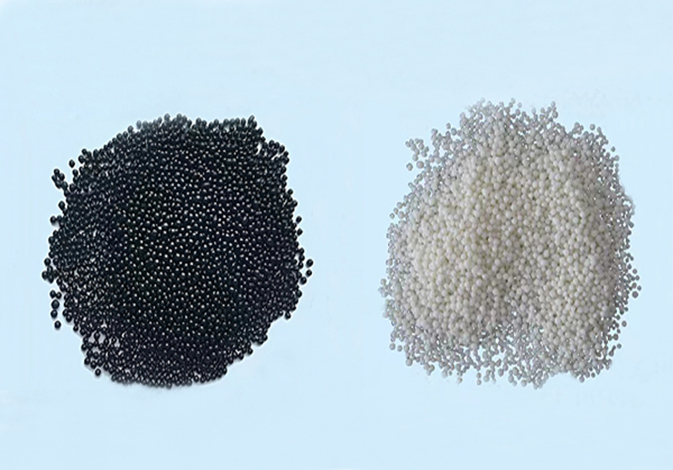

White plunger lubricant shot beads do not contain graphite, are high-temperature resistant have good lubricity, and are widely used in hot chamber and cold chamber die casting machines. The granule size of the product is 0.5-1.0mm,1.0-1.5mm,1.5-2.0 mm,2.0-2.5 mm, and 2.5-3.0 mm, it can be in the shot sleeve and injection on melting and rapid expansion in the shot sleeve and on plunger tips. Its superior capillary effect in the shot sleeve to form an excellent lubricating film, is more convenientPlunger tip

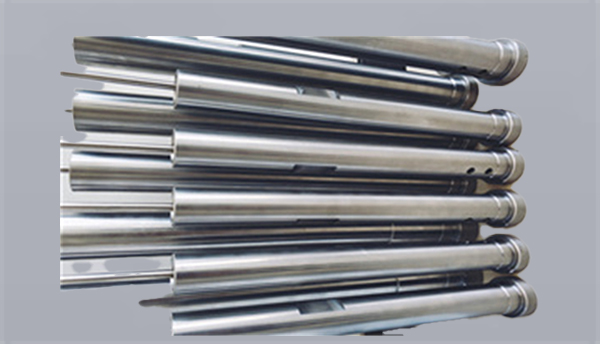

We have all kinds of plunger tips suitable for different production needs. The specific choice depends on the material and design requirements of the casting. You can tell us your specific needs and our professional engineers will help you choose the most suitable plunger tip accessories for your machine.Plunger piston/Injection piston/Injection piston rod

The material of the plunger piston adopts GB40Cr, the heat treatment is adjusted to t245-265, the surface is blanched, and the high-frequency quenching the hr38-42.The diameter is 10-500mm, and it is durable.Shot Sleeve/Integral Shot Sleeve

The shot sleeve is a critical element of the aluminum die-casting process. We have various shot sleeves for you to choose from and they can fully match different die-casting machine models. You can tell us your machine model and our professional engineers will recommend the most suitable shot-sleeve accessories for you.Shot Beads/ Plunger Lubricant Granule

Shot beads are a kind of lubricating material. They are specially used in metal stamping, forming, and other processing processes to reduce friction, and improve mold life and processing efficiency. We have two kinds of shot beads for you to choose from, blackshot beads containing graphite and white shot beads without graphite. Both have excellent lubrication properties, which can reduce mold wear and extend service life.Die Casting Release Agent/Die Casting Mold Release Lubricant

The die-casting release agents can help the castings separate from the mold and ensure their integrity and accuracy. Our company has various release agent models for you to choose from. If you have more specific requirements, our staff can recommend the release agent that can provide the best release performance based on the metal material, complexity of the molds, etc.LK Cold Chamber Die Casting Machine DCC630

DCC630 Aluminum Die Casting MachineTo Be Better in Every Way1. Energy saving systemSaving on average >50% of energy consumption by equipping with servo motor.2. Quick die change system (optional)Reduces manpower and machine idle time during mold change.3. Quick die change system (optional)RLK Cold Chamber Die Casting Machine DCC320

Locking Force: 1450KN Die Height: 250-500mm Space Between Tie Bars: 429x429mm Shot Weight: 1.6Kg Casting Area Max:362c㎡LK Cold Chamber Die Casting Machine DCC160

Locking Force: 1600KN Die Height: 200-550mm Space Between Tie Bars: 460x460mm Shot Weight: 1.8Kg Casting Area Max:400c㎡

SIGN UP FOR OUR NEWSLETTER